Home > Products > glazed tiles Roll Forming Machine > Machine producing metal tiles glazed roll forming machine/glazed roofing sheets cold forming machine

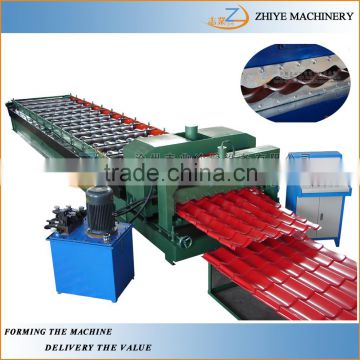

Machine producing metal tiles glazed roll forming machine/glazed roofing sheets cold forming machine

- 30 Set / Sets per Month

- tianjin

- T/T L/C D/P D/A Credit Card PayPal

You May Like

-

Automatic Colore Glazed Steel Tile Rool Forming Machine/Glazed Roof Sheets Cold Making Line

-

Wall &Roof Panel Machinery For Glazed Tile/Glazed Tiles Steel Forming Machine

-

Structural Glazed Tiles Roll Forming Machine/the production line of glazed tile machine

-

Aluminium Step Tile Roofing Panels Cold Making Machine/Glazing Tiles Cold Forming Machine

-

Steel Roofing Glazed Tile Process Line/ Express step roof tile glazed tile roll forming machinery

-

metal step tiles making machine / glazed tile forming press machine

Product Details

| Place of Origin | Hebei, China | Brand Name | ZY | |

| Model Number | ZY | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Machine producing metal tiles glazed roll forming machine/glazed roofing sheets cold forming machine

General information for the Machine producing metal tiles glazed roll forming machine/glazed roofing sheets cold forming machine

The tiles produced by this machine are widely used in all kinds of factories, houses, warehouses and simple steel shed, and with beautiful appearance, high efficiency and reliable working.It consists of feeding platform, main molding core, shearing mechanism, hydraulic station, computer control cabinet, high precision counter and so on.

Detailed components introduction for the Machine producing metal tiles glazed roll forming machine/glazed roofing sheets cold forming machine

1.. Manual Decoiler of the Machine producing metal tiles glazed roll forming machine/glazed roofing sheets cold forming machine

1):coil inner diameter: 450-550mm

2):coil max width: 1250mm

3):max carrying capacity: 5000kg

Usage:It is used to support the steel coil and uncoil it in a turnable way.

Passive uncoil pulled by roll forming system

Hydraulic fully automatic style is optional

2.. Coil feeding part of the Machine producing metal tiles glazed roll forming machine/glazed roofing sheets cold forming machine

Usage:Put the raw material(steel plate) through the beach to manufacture and process,

it can guarantee that the products are neat, parallel and everything is uniformity.

Please refer to the equipment regulation to know the function of locate angle iron.

3.. Main roll forming machine part of the Machine producing metal tiles glazed roll forming machine/glazed roofing sheets cold forming machine

1).roller material: 45# steel with hot treatment at 52-68 degrees, hot chormed on the surface to make sure its hardness.

shaft material: solid shaft(not hollow style), around 70kg/pc, to make sure the strength of it.and final profile shape are perfect in this way.

shaft diameter: normally is 72mm.

2).power: normally 7kw in total

3).transmission model: gear and chain

4).controlling model: PLC controlling system, fully automatic.

5).Forming speed: 0-17m/min

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor

reducer drive, chain transmission,roller was chromed which can keep the molding plate surface

smooth and not easy to be marked when it is working

4.. Automatic cuttting system of the Machine producing metal tiles glazed roll forming machine/glazed roofing sheets cold forming machine

2).Cutting system: advanced hydraulic drive, automatic cutting after forming, no distorting or

wasting, high level safety factor.

It adopts the hydraulic drive and automatic encoder to cut the accurate length you set on the computer.The tolerance is within 10m±1mm

Material of blades: Cr12 quenched

Power supply : hydraulic power

Components:It contains one set of blade, one hydraulic tank and one cutter machine

5.. Computer controlling part of the Machine producing metal tiles glazed roll forming machine/glazed roofing sheets cold forming machine

1).PLC brand: Normally, it is Delta. Mistubishi, Panasonic, Siemens are optional.

2).working model: fully automatic and manaul

3).working language: normally are English, Chinese,Russia. Can be set as per your requirements.

6. Hydraulic station of the Machine producing metal tiles glazed roll forming machine/glazed roofing sheets cold forming machine

1).including one motor,one oil tank,one magnetic valve,one pressure gage, hydraulic oil tube

2).3kw,4kw,5.5kw,will be adopted as per your profile sheet.

The assembling production flow of the Machine producing metal tiles glazed roll forming machine/glazed roofing sheets cold forming machine

↓

↓

↓

↓

↓

Machine producing metal tiles glazed roll forming machine/glazed roofing sheets cold forming machine can be packed into one 20' feet container or 40' feet container. We have good relationship with the shipping agent. Either you can find the shipping line at your side or we can help you.

We will offer technical support for all the roll forming machines the whole life. 2 years free spare parts replacement and maintaince. Our international technicians can be reach your workshop at the first time if your machines has problem.

Cangzhou Zhiye Cold Forming Machinery Co., Ltd is the manufacturer specialized in various cold forming machineries and automatic production lines. Main products are: roofing/wall panel roll forming machines, tile roll forming machines, C/U/Z purlin roll forming machines, floor decking roll forming machines, steel frame truss roll forming machines, pipe roll forming machines and customerized machines.

For further information, welcome to contact at:

James LEE

SKYPE: rollformingmachines

Mob: +86 157 3274 8855

Whats App: +86 157 3274 8855

Sincerely wish to estabilish win-win business relationship with you!

Contact Us

- Cangzhou Zhiye Cold Forming Machinery Co., Ltd.

- Contact nameJames Lee Chat Now

- Phone86-317-8260876

- Addressbotou industry zone, Cangzhou, Hebei

Product Categories

New Products

-

automatic glazed cold rolling wall and roof steel making line/Glazed roof tile roll forming construction machine

-

Steel Colored Step Glazed Roof Tile Making Machine/glazed tile roll forming machine

-

Steel Roof Corrugated Sheet Wall Panel Steel Structural Glazed Tiles Roll Forming Machine

-

Glazed Roof Sheets Cold Forming Machine For Metal Building / colored glaze roof tile forming machine

-

Manufactures Steel Colored Step Glazed Roof Tile Making Machine/lazed steel tile roll forming machine

-

Glazed Steel Tile Rolling Forming Mill/Roofing Step Tiles Roll Forming Production Line

-

925 Meta Glazed Tile Cold Rolling Machine / glazed roof tiles rolling forming line

-

Metal Glazing Step Tiles Roller Former Line/Glavanized Steel Roofing Glazing Sheets Production Line

-

Various Customized roll forming machine glazed tile sheet cold forming line

-

Zinc Glazed Steel Roofing Sheet Roll Forming Machine/metal glazed roof sheet making line/equipment

-

steel glazed roof tile forming machine roofing sheet making line

-

Metal Glazing Step Tiles Roller Former Line/Zinc Glazing Step Sheet Roll Forming Making Euipment

-

steel glalvanized metal aluminum glazed sheet roof & wall panel making machine

-

Color Automatic Glazed Tile Steel Roll Forming Machine Roofing Process Line

-

High quality and economical metal glazed tile cold forming machine

-

Color Coated Steel Roof Glazed Iron Roofing Tiles Making Machine

-

power 5.5KW roofing used gutter downpout pipe cold making machine

-

glazed roof tiles making machine manufacturer/automatic glazed sheets cold forming machine

-

large assortment k style downspout cold forming machine/k style downspout making machine

-

European profile colored steel interlocking step roofing sheets making machine

-

aluminium roofing sheets roll forming step tiles machine/PPGI Metal Roofing Sheet Cold Forming Line

-

Glazed Tiles Cold Rooling Forming Equipment/Step Sheets Making Line

-

glazed roof tile cold forming machine/steel roofing sheet rolling making line

-

metal aluminum glazed sheet roof wall panel making machine

Popular Searches

- spare parts

- machine parts

- cnc machining

- garden shear

- Spare Part

- belt sander

- riveting machine

- air shear

- Aircraft Parts

- aluminum parts

- machinery part

- precision machining

- cnc parts

- aerospace machining

- cnc turning part

- Cnc Machining Part

- Machine Part

- Aluminum Cnc Machining Part

- Cnc Machine Part

- Cnc Precision Machining Part

- Machined Metal Part

- Cnc Milling Part

- Cnc Turned Part

- Repair Part

- Package Part

- Machine Spare Part

- Replacement Part

- aluminium heatsink

- plastic part

- lead alloy

Recommended Products

- Square Round Tube Saw Cut off Equipment Manual Pipe Cutting Machine

- Solar Waste Recycling Plant | PV Waste Processing Equipment

- Exhaust Pipe EGR Tube Flaring Expander End Forming Machine, Auto Metal Tube End-Forming Steel Pipe Reducing/Shrinking Machine

- Automatic Stainless Steel Copper Aluminum Pipe End Reducing Machine Pipe End Shrinking Machine Tube End Forming Machine

- Manufacture Sells PLC Control 4 Stationes Pipe End Forming Machine

- Automatic Reducing Expanding Flanging Pipe End Forming Machine

- Round Tube Square Tube Reducing Forming Machine Automatic Pipe End-Forming Machine

- Hydraulic Stainless Steel Pipe End Expanding Machine for Pipe Expander or Tube Reducer

- Multi Station Automatic Square Tapper Pipe Tube End Reducing Forming Machine Price

- Four Stations Pipe Forming Machine with Round Tube

- Tube Taper End Forming Machine Automatic Metal Tube Reducer Pipe End Shrinking Machine

- Pipe Tube End Forming Machine for Expanding Reducing Flaring

Find Similar Products By Category

- Machinery > Metal & Metallurgy Machinery > Other Metal & Metallurgy Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

James Lee

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

James Lee

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile