Home > Products > machine parts > extruder single screw and barrel for yarn

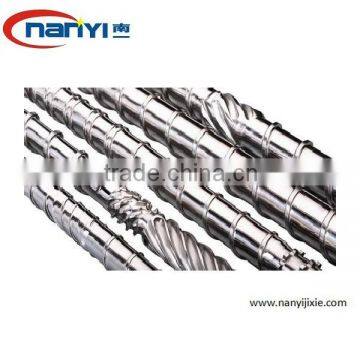

extruder single screw and barrel for yarn

- 200 Set / Sets per Month

- Wenzhou or Ningbo

- T/T Credit Card

You May Like

-

extrusion single screw and barrel for wire

-

38 crmoala screws and barrels for extruder machine manufacture

-

38 crmoala stainless screws and barrels for extruding machine

-

high out-put screw and barrel for extruder machine

-

PP.HDPE nitrided single screw barrel for extrusion

-

single screw extruder for making PE/PP plastic products

Product Details

| Place of Origin | Zhejiang, China | Brand Name | NanYi | |

| Model Number | all types |

Product Description

Specifications

extruder single screw and barrel for yarn38CrMoAIA alloy steel screw

High corrosion and wearable

extruder single screw and barrel for yarn

1.We are a professional company specialized in manufacturing many types of screw, the barrel can be applied on all types of injection moulding machine,rubber hot-feeding extruder, rubber cold-feeding extruder, pin barrel cold feed extruder, plastic extruder with different specifications.

3. The material of screw: manufactured with high-quality nitro alloy steel, applying the method of hardening and tempering and nitriding, thus it enjoys the characteristics of long working life, wear resistance, and anti corrosion. Besides, the technique of hard alloy spraying or chrome plating can be used on the working surface of screw, which will make it have better using effectiveness.

Product Specifications:

Base Material | 1)38CrMoAlA(JIS SACM645) 2)Cr12MOV(JIS SKD-11) |

Bimetallic Alloy Materials | 1)Fe-based alloy 2)Ni-based alloy/Deloro alloy |

Surface Treatment | Heat Treatment High Frequency Treatment Nitriding treatment(120 Hours) Depth of Nitrided Layer: 0.5-0.8 mm Hardness of Nitrided Layer: 900-1020Hv (HRC56°-65°) Hard Chrome Plating treatment: Thickness of Hard Chrome Plating Layer: 0.05-0.10mm Hardness of Hard Chrome Plating Layer: ≥950HV Nickel alloy plating.treatment: Bimetallic Barrel/Cylinder: Centrifugal Casting (Inlay Alloy) Bimetallic Screw: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness of Bimetallic Layer: HRC55°-72° |

Technical data | Depth of Nitrated Layer: 0.40-0.70mm Hardness of Nitration: 950-1050Hv Fragility of Nitration: ≤ 2grade Hardness of Bimetallic Layer: HRC55-62 Thickness of bimetallic layer:2-3mm |

Material Application | 1)General Plastics 2)ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc 3)PA + GF(Glass Fiber) 4)Flame-resistant Reinforced Plastics 5)Modified Engineering Plastics 6)All kinds of Mixed Recycled Material(in Scrap or Granule),etc |

General Terms | Means of transport: Ocean, Air, Express Production time: About 25 days after we receive the deposit and lead time will different according to the order quantity! |

Our products advantages | 1)High productivity 2)Wonderful plasticizing 3) low energy consumption 4)Wearable and Durable |

We can produce the screw barrel according to your requirements | |

Workshop:

Contact us

Wenzhou NanYi Plastic Machinery Co.,Ltd

ADD:No.268, National Road104, Aojiang Town, Wenzhou City, Zhejiang,China

Website: http://www.nanyijixie.com or

http:// zjnymachine.en.china.cn

Tel: +86-577-63696280 Fax:+86-577-63690818

Mob:+86-13867739043

Skype: lissy.xie

Contact Us

- Zhejiang Nanyi Plastic Machinery Co., Ltd.

- Contact namelissy xie Chat Now

- Phone86-577-63696280

- Address: No.268, National Road104, Aojiang Town, Wenzhou, Zhejiang

Product Categories

| Accessorial Machinery | Circular Loom | Laminating machine | machine parts |

| New Products | nonwoven fabric making machine | PP/PE Extrusion machine | Printing machine |

| Winding Machine |

New Products

-

barrel single screw extruder

-

single screw and barrel plastic extruder

-

extruder mould for PP woven sacking machine

-

Plastic extruder die head for PP woven sacking machine

-

extruder die head mould for plastic extruder/wire drawing machine

-

single screw and barrel plastic extruder for tape drawing machine

-

double beam SS Non woven fabric making machinery

-

double beam SS PP Spunbonded Non woven fabric making machine

-

PP Spunbonded Nonwoven fabric production line

-

S/ SS/SMS PP Spunbonded Non woven fabric production line

-

non woven fabric making machine for bag

-

pp spunbonded nonwoven fabric making machine for shopping bag/baby diaper/face mask

-

NY-3200 full automatic Germany technology good quality spunbond nonwoven fabric making machine from China

-

high output pp spunbond non woven fabric making machine from China

-

flat yarn wire drawing machine

-

High speed pp yarn wire drawing machine

-

High speed flat film yarn extruding machine/tape drawing machine

-

plastic flat yarn extrusion equiment

Popular Searches

- ac barrel

- a.1. barrels

- a.1. barrel

- aire rings

- aire ring

- aires ring

- aires rings

- and barrel

- as barrel

- at barrel

- barrel of slime

- barrel bat

- be barrels

- bin barrel

- block barrel

- barrel back

- barrel printed

- burn barrell

- barreles for beer used

- car barrel

- Changing Device

- changing devices

- cord blades

- cord blade

- Ce Barrel

- embosser roller

- erema

- Good Barrel

- good barrels

- grip barrel

Recommended Products

- Automatic glue turning and mixing machine

- YC-ML003B--Open-close mixer

- Automatic glue turning and mixing machine

- YC-ML003B--Open-close mixer

- Automatic glue turning and mixing machine

- Heat Insulating Sealing Pad Used for Underwater Pelletizing Production Line for PP PE EVA Granules

- Thermal Insulation Waterproof Sealing Gasket Used for Underwater Pelletizing System for PP PE Granules

- PP PE Granules Cutting Tool Pelletizing Knife for Underwater Pelletizing Production Line

- Polyolefin Underwater Pelletizer Spares Pelletizing Knife Holder for Fixing Pelletizing Knives

- Metal-Ceramic Pelletizer Knife for Polyolefin Underwater Granulation Machine Extruder

- PP PE Plastic Granules Manufacture Extruder Parts Granulation Die Plate for Underwater Pelletizing System

- Automatic Soft PVC Freezer Door Gasket Making Machine with online magnetic strip inserting machine

Find Similar Products By Category

- Machinery > Plastic & Rubber Machinery > Plastic & Rubber Machinery Parts

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

lissy xie

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

lissy xie

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile