Home > Products > Finned Tubes > Stainless Steel Finned Tube for heat exchanersE

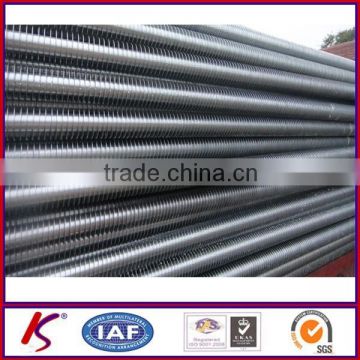

Stainless Steel Finned Tube for heat exchanersE

- 10000 Piece / Pieces per Month

- shanghai

- T/T

You May Like

Product Details

| Thickness | 0.5, 16 | Section Shape | Round | |

| Outer Diameter | 12 - 219 mm | Place of Origin | Jiangsu, China | |

| Secondary Or Not | Non-secondary | Application | Gas Pipe | |

| Technique | ERW | Surface Treatment | Other | |

| Alloy Or Not | Is Alloy |

Product Description

Stainless Steel Finned Tube for heat exchaners

Specification of heat exchangers finned tube

Base Tube O.D | Base Tube Thickness (mm) | Fin Height (mm) | Fin Thickness(mm) | Fin NO.(Pc) |

25.4 mm ~152.4 mm | 1.0 mm ~4.0 mm | 5.0 mm ~16.0 mm | 0.89 mm ~1.5 mm | 2 ~ 36 |

Base Tube Material | Fin Material | Tube Length (Mtr) | ||

Carbon Steel ,Alloy Steel ,Stainless Steel | Carbon Steel ,Alloy Steel ,Stainless Steel | ≤ 15Mtrs | ||

Production of heat exchangers finned tube

Longitudinal Finned Tube produces by high frequency resistance welding fins in the longitudinal direction with the length of the tubes. Fin strip material shall be compatible with and suitable for standard frequency resistance welding to the specified tube material. Before applying the fins, the tube outside surface shall be properly prepared to ensure that the fin-to-tube weld is sound. The fin strip is first bend into U-shaped channel, so that each leg of the U will be a fin. The channels cut into the suitable length and oriented along the length of the tubes and resistance welded in place. The channels weld in pairs, diametrically opposed -- therefore the number of fins specified always be a multiple.

For a given pipe or tube size, the desired heat transfer surface area per unit length of tubes can be obtained by specifying the appropriate fin height and/or number of fins. The maximum number of fins depend upon the tube OD - larger OD tube can accommodate more number of fins.

The operation of "cut and twisted" longitudinal finned tubes consists of cutting through the fin channels circumferentially at specified intervals along the tube length. The fins are then bent (or "twisted") on one side of each cut, creating a discontinuity that promotes turbulent fluid flow, thereby enhancing heat transfer efficiency.

Application of stainless steel heat exchangers finned tube

The choice of longitudinal finned tubes VS helical finned tubes seems to be governed mainly by geometric considerations. For example, some heater configurations consist of finned tubes inserted inside other tubes, longitudinal finned tubes are the obvious choice for such applications. In other cases, users prefer longitudinal finned tubes for installations where the tube will be oriented in a vertical direction -- the fin orientation facilitates fluid drainage on the fin side of the tube.

Like welded helical finned tubes, this welded steel configuration can be used for practically any heat transfer application, and is particularly suited to high temperature, high pressure applications. The important features of this configuration are efficient, effective bond of fin to tube under all conditions of temperature and pressure, and ability to withstand high fin-side temperatures.

Advantages of stainless steel heat exchangers finned tube

Provide 8 to 12 times the heat transfer area of bare tubes.

Are more efficient than bare tubes.

Provide smaller exchangers due to increased Heat Transfer area.

Often provide a more economical selection.

Fins can be "Cut & Twist" to increase shell side fluid turbulence and improve heat transfer.

For rapid quoation, please send requirement included:

Number of pieces

Base Tube: diameter, thickness, length and material specification

Fins: height, thickness, number, length, material specification and unfinned ends.

Contact us

Skype: yuan.miley

Tel:86-510-85871033

Fax:86-510-85871386

Office:Rm.2216,Wanda Plaza,Liangxi Rd,Binhu District ,Wuxi

Factory: Shiliu Road, Hongxiang, Hudai, Binhu, Wuxi, 214161, Jiangsu, China

Contact Us

- Wuxi Kaisheng Electricity Petrochemical Equipment Co., Ltd.

- Contact nameKai Sheng Chat Now

- Phone86-510-85539300

- AddressShiliu Road, Hongxiang, Hudai, Binhu, Wuxi, 214161, Jiangsu, China, Wuxi, Jiangsu

Product Categories

| Bars | Finned Tubes | Flanges | Gaskets/Spacers |

| New Products | Parts for Pressure Vessels | Pipe end cap/Seal head | Studded Tubes |

| Tube Sheet & Baffles | Tubes |

New Products

-

Copper Finned Tube----Integral low fin tubes from China

-

G Type Finned Tubes on sale

-

Longitudinal Finned Pipe & Finned Tubes with prime quality

-

Stainless steel,Alumnium Plugs Finned Tube

-

Stainless steel,Alumnium Low-finned Tubes

-

Promotional Heat Exchange finned tube fin pipe

-

Promotional Heat Exchange copper-embedded-or-g-finned-tube

-

Alumnium Extruded fin tube

-

Finned Tube | Precision Tube for heat exchangers

-

Boiler/heat exchanger/finned/u and u-finned tubes

-

Finned Tube

-

Spiral wound finned Tube for boiler parts

-

Aluminum extruded fin tubes Air cooled heat exchanger

-

Crimped Type Finned Tubes Air cooled heat exchanger

-

Integral low fin tubes Air cooled heat exchanger

-

Longitudinal Finned Pipe & Finned Tubes for boilers

-

G Type Finned Tubes for boilers

-

spiral finned tube (Longitudinal/Spiral/Square)

-

Tube sheet/baffle/flange/finned tube/studded pipe/nozzle manufacture

-

Finned Tubes Stainless steel & Carbon steel

-

Air condition finned tube

-

all kinds of finned tube,stainless finned tube,finned pipe

-

Alloy steel Square /spiral .longitudinal stainless finned tube

-

customized all kind finned pipe,ERW finnd pipe ,alloy finned pipe

Popular Searches

- copper tube

- Copper Ingot

- copper clad aluminum

- non-ferrous metal

- Copper Alloy

- hpmc

- micro fiber

- heater tube

- portland cement

- rapid hardening cement

- Hydroxypropyl Methyl Cellulose

- Copper Bars

- copper coil

- copper sheet

- copper rod

- brass rod

- brass copper

- copper pipe

- copper cathode

- Copper Round Bar

- Brass Bar

- Copper Flat Bar

- Copper Rod Bar

- Brass Round Bar

- Copper Ingots

- copper plate

- Brass Ingot

- Copper Pipes

- copper tubing

- copper bar

Recommended Products

- Henggang produces low temperature resistant steel pipe Q345C Q345B Q390E low-alloy pipe Q345d seamless steel pipe

- Seamless steel pipe Q345bQ355 alloy steel pipe, national standard non-standard ruler, double length seamless pipe

- Baosteel Q390E alloy steel pipe Q345C seamless steel pipe Q345D Q345E seamless pipe low-temperature pipe

- Henggang produces low temperature resistant steel pipe Q345C Q345D Q345E seamless steel pipe Q390E alloy steel pipe

- Henggang produces 16mnD pickled steel pipes Q345C seamless steel pipes Q345D Q345E seamless pipes for cold storage

- 35 # steel pipe 16Mn seamless steel pipe Q355B hot-rolled seamless steel pipe factory

- 35 # precision annealed pipe 45 # steel pipe 10 # fluid conveying pipe 35 # seamless steel pipe

- ASTMA210C Seamless Steel Pipe ASME SA210C A210-C High Pressure Boiler Tube

- Baotou Steel seamless steel pipe API 5L X42 X52 X60 X65 PSL1 seamless steel pipeline for oil and gas

- API 5CT casing Baotou Steel seamless steel casing with buttress thread

- Baotou Steel 244.48mm casing N80 seamless steel casing SC LC R3 casing pipes for oil drilling

- 339.72mm casing K55 J55 seamless steel casing BTC R3 casing pipes for oil drilling

Find Similar Products By Category

- Minerals & Metallurgy > Steel > Steel Pipes

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Kai Sheng

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Kai Sheng

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile