Micro Brewery Equipment/beer Brewing System/beer Fermenter/pilot Beer System

Specifications

micro beer brewing system all used SUS3041.Capacity:200L/D

2.Usage:for brewery pub hotel or restaurant

3.SUS 304 material

micro brewery equipment/beer brewing system/beer fermenter/pilot beer System

micro beer brewing system all used SUS304 /Mini Home Beer Brewing Equipment/ Beer Brewery System

pub beer brewing equipment/micro beer brewery equipment

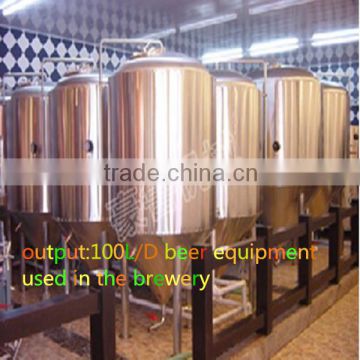

New! (Compact type)Complete 100l mini beer brewing system from crushing to selling system

resorts beer brewery making machine

1.Capacity:100L/D

2.Usage:for brewery pub hotel or restaurant

3.Control:PLC

4:Materials:Red copper,s304

Mini Home Beer Brewing Equipment/ Beer Brewery System

Applications: Widely used in brewery,bar,hotel,home brewing.

Specifications:

The mashing tun/kettle is made out of stainless steel or copper and has a typical capacity of 5, 10, 15, 20, 25, 30 or 40hL..

A mashing tun, also called mashing kettle, is used for mixing and heating a mixture of malt and water in a process called mashing. It is designed to do both step mashing and infusion mashing.

A kettle, also called boiling kettle, is used for boiling wort, coming from the lauter tun, with hops and sometimes other adjuncts.

Depending on the size of the brewery mashing and boiling can be done in the same vessel or separate vessels can be foreseen. The mashing tun/kettle is made out of stainless steel or copper and has a typical capacity of 5, 10, 15, 20, 25, 30 or 40hL (1hL or hectoLiter equals 100 liters).

Heating is done with steam that heats the side and bottom of the cooking. Steam heating systems are a lot better than direct heating through gas or thermal oil as they are more powerful, very responsive, and prevent the mash from caramelizing and sticking to the bottom of the vessel. Furthermore a steam operated brew house gives a better "rolling boil" and a better acidity extraction from your hops.

Another important aspect in the brew house design is the location of the mixing mechanism (agitator) in the cooking tun. This mixer is driven by a motor is always located under the cooking tun. This is not only visually far more attractive, but its solves the problem that all breweries have which use motors located on top, namely the drip of grease into the beer. If this happens, it ruins the entire brew. With our systems, this can not happen.

Finally the mashing tun/kettle can be equipped with a number of additional accessories facilitating the brewing and cleaning operations

Outside surface | Stainless steel or red copper,THK:1.5mm-3mm |

Inner surface | S.S.304,THK:2mm-4mm |

Top shape | Seal head or conical head |

Heating method | electricity/Steam |

Insulation layer | Protected by polyurethane,THK:70-100mm |

Polishing | ≤0.4µm |

Manhole | Side upward or your requirements |

Plate heat exchanger | 4m² |

Agitator | Raking system conneted into a top reducer |

Send Inquiry to This Supplier

You May Also Like

-

Wine Fermentation TankNegotiableMOQ: 1 Set

-

Coffee Bean Sorting Machine Grain Gravity Separator Machine Caraway Seed Density SeparatorNegotiableMOQ: 1 Set

-

Supply OEM/ODM Bean Sprout MachineNegotiableMOQ: 1 Piece

-

Heavy-Duty 4m High Basketball Court Fence With Anti-Climb DesignNegotiableMOQ: 1 Acre

-

2019 Shanghai Genyond Small Scale Commercial Tofu Production LineNegotiableMOQ: 1

-

Peanut Cutting Machine Almond Strip Cutting Machine Fast Cutting SpeedNegotiableMOQ: 1 Set

-

Factory Price Bean Bud Seedling Machine/Bean Sprout Growing Machine For SaleUS$ 1,500 - 7,999MOQ: 1 Set

-

Large Output Sprouts Cleaning Machine Vibration ShellerUS$ 1 - 2,500MOQ: 1 Set

-

Professional Manufacturer of Soybean Milk Process MachineUS$ 1,500 - 3,000MOQ: 1 Set

-

Green Bean Sprout Making Machine/machinery/makerNegotiableMOQ: 1 Set