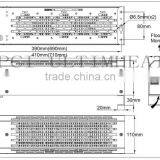

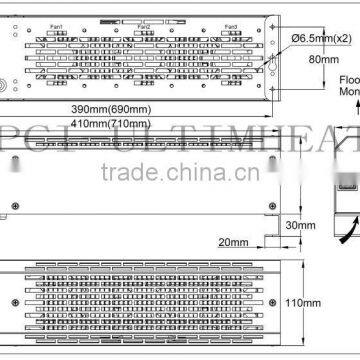

Type 9CH, Fan Heaters, 110mm Compact Range, Upward Blowing Models

Specifications

Fan heaters, 110mm compact rangeUpward blowing models

Type 9CH

Main applications

These heavy duty fan heaters, are characterized by their very small size, and are designed for professional, commercial or industrial applications.

They are equipped with 3 ultra-thin fans, with a 2 pole, illuminated on-off switch, an adjustable control thermostat and a safety thermostat.

Although their heating elements are shielded and sealed, their fans and control box are not waterproof, and they should not be used outdoors. Their insulation class 1 does not allow to use them in bathroom and in all places requiring Class II insulation. They are not designed for use in hazardous environments.

They exist with painted steel or stainless steel frame.

The main applications are heating of professional workshops, heating small volumes such as bungalows, cranes cabins, construction equipment, wagons or locomotives cockpit, technical rooms, ovens, containers, dryers. They can also be used as electrical heaters for large size electrical cabinets.

Main features

Dimensions: 2 body lengths: 410 or 710mm

Ingress protection: IP41

Heaters: 3 finned elements in 304L stainless steel. Fins 25x50mm 304 stainless steel. Surface load 3W/cm²

Frame material: 0.8mm thick sheet, high strength (Withstands +100kg distributed load), two versions:

- Galvanized steel sheet with black epoxy paint

- 304 stainless steel sheet.

Fans: 3 fans of 80 x 80mm, flow 3 x 30m3 /h. L10 life expectancy: 50.000 h (>5 years) at 25ºC. L10 refers to the time at

which statistically, 90% of the fan will still be operative. Life expectancy is reduced by about 50% when ambient temperature rises to 50-70°C.

Controls: adjustable bulb and capillary control thermostat, range 4 to 40°C, and fail safe high limit manual reset thermostat for protection against air outlet obstruction or fans failure.

Electrical connection: by grounded euro plug, 2 meters, 3x1.5mm²

Mounting: 2 removable legs can be mounted under the frame (floor mounting) or on the side (wall mounting).

Voltage: 230V, 50/60Hz. Other voltages available on request.

Power: 1500W (410mm) and 3000W (710mm)

Ambient temperature : -20 to +60 ° C

Net weight: 4.1kg (410mm) ; 5.9kg (710mm)

Option: customization accepted

References with 230V power supply

Black painted steel frame | 304 stainless steel frame | ||||

References | Power (W) | L | References | Power (W) | L |

9CH14033023150HB | 1500 | 410 | 9CH14033023150H4 | 1500 | 410 |

9CH17033023300HB | 3000 | 710 | 9CH17033023300H4 | 3000 | 710 |

JPCI Controls (Foshan Gaoming) Co., Ltd

Member of Ultimheat alliance

Ultimheat is a registered trademark, all rights reserved

Contact : Michelle Mai

T: +86 757 88638729

F: +86 757 88681850

Website:

Company profile:

Established in China since 2000, with French technology and investment, our company is proud to have more than 60 years experience in manufacturing electromechanical components and 30 years experience in manufacturing safety component for Spas, swimming pools and hot tubs. This experience, combined with high tech equipment and high tech raw materials let us develop the new components needed by rapid expansion of Asian and Chinese market.

In our new factory, on more than 8000 square meters production lines, we have two manufacturing divisions:

Division one is producing components:

Thermostats, energy regulators pressure switches, level switches, flow switches, fire detection fusible links, heating elements and ceramic connection blocks.

Division two is producing complete assemblies and sub assemblies on customer specifications:

Swimming pools heaters, heat pumps backup heaters, spas heaters, small water heaters, immersion heaters, aluminum foils heaters, baseboard and convection heaters sub assemblies

Our R&D team develops new products upon customer specification, taking care of international safety standard (UL, CE, etc.).

We produce our own stamping, bending, plastic injection, zinc alloy injection, and machining.

We are equipped with up to date automatic and CNC TIG welding and laser welding equipment and ultrasonic welding checking.

We have our own climatic room, corrosion testing loops, salt spray testing, and more than 30 specific equipments for products life testing.

Our income quality control laboratory is equipped to check raw material (plastics, metals) physical characteristics and dimensions.

Our finished product control laboratory has more than 200 machines to calibrate and check temperature, pressure, level and flow controls.

From the raw material to the finished product we control every production step. Meet your control equipment demand rapidly and safely is our consistent promises.

View this Supplier's Website

Basic Information

| Product/Service Sell): | Flow switches, level switch,pressure switch, thermostat,heating elements, back up heaters for heat pumps |

| Number of Employees: | 200 to 300 People |

Trade & Market

| Main Markets: | North America |

| Total Annual Sales Volume: | US$2.5 Million - US$5 Million |

| Export Percentage: | 60% |

Factory Information

| Factory Size (ters): | 10,000 square meters |

| Factory Location: | Datian Cunkou, Fuwan industrial zone,Gaoming of Foshan, Guangdong province,China. |

| Number of Production Lines: | 15 |

| Number of R&D Staff: | 5-10 |

| Number of QC Staff: | more than 15 People |

| Management Certification: | ISO9001/14001 |

| Contract Manufacturing: | Customized products on request (MOQ apply), OEM developments welcome. |

Send Inquiry to This Supplier

You May Also Like

-

Home Using Different Capacity Electric Water Heater With Booster PumpNegotiableMOQ: 1 Forty-Foot Container

-

IXP4/CE,EMC /GS 250/500w Electric HeaterNegotiableMOQ: 500 Pieces

-

Household Electric Heater, Small Heating FanUS$ 3.5 - 4MOQ: 10 Pieces

-

GMO Electric Water Heater | High Quality Electric Water HeaterUS$ 150 - 1,001MOQ: 1 Set

-

Handy HeaterNegotiableMOQ: 500 Pieces

-

Solar Energy TechnologyNegotiableMOQ: 1 Piece

-

Sell Aluminum Die-Casting RadiatorsNegotiableMOQ: 1 Piece

-

Water HeaterNegotiableMOQ: 1 Piece

-

PTC Fan Heater 1800W 918CNegotiableMOQ: 2000 Pieces

-

80W, 220-240V/50Hz Electric Towel Dryer. H0113US$ 14 - 19MOQ: 1000 Pieces