Home > Products > 3~Tubothal Heating Elements > Industrial Furnace Ceramic Bobbin Heater Heating Element

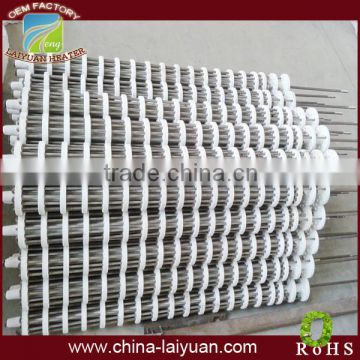

Industrial Furnace Ceramic Bobbin Heater Heating Element

- 2000 Piece / Pieces per Month

- Shangha/Ningbo

- T/T Credit Card PayPal

You May Like

-

Industrial Furnace IR Ceramic Bobbin Heater pipe

-

High Temperature High Temperature ceramic bobbin heater for Heating Element/Innovacera for Heating Element/Innovacera

-

Electric Ceramic Bobbin Heating Element IR Tube Heater

-

24KW Electric Industrial Thermal Treatment Stove Heater Bobbin Heating Element

-

2kw~40kw IR Customized Ceramic Bobbin Heater Pipe

-

Ceramic bobbin heater/Electric ceramic bobbin heater core

Product Details

| Condition | New | Type | Infrared Heater | |

| Power Source | Electric | Place of Origin | Jiangsu, China | |

| Brand Name | Laiyuan | Model Number | LY-CBH-15033 | |

| Dimension(L*W*H) | D=80mm L=960mm | Weight | 5.5kg/pcs | |

| Voltage | 380VAC | Power(W) | 15KW | |

| Certification | CCC/CE | Warranty | 1 Year | |

| After-sales Service Provided | Overseas third-party support available |

Product Description

Industrial Furnace Ceramic Bobbin Heater Heating Element

The advantages of Bobbin Heater :

| 1. The controllability of aural inside furnace can be guaranteed. |

| 2. The control of temperature,assemble and maintainace are very convenient and can be easy to sealed. |

| 3. The cubage of hearth is enlarged and throughput is improved because of no muffle po |

| 4.Strong heating ability and high efficiency |

| 5. The refractory steel material is save. |

Bobbin Heater Usage:

1) Avoid to heat over the temperature and overload for long time |

| 2) When the furnace temperature higher than 400 degrees, avoid to be cold immediately. |

| 3) Unload and load the material can’t touch the ceramic heater |

| 4) Pay attention to the red and blue buttons when the furnace on work, and change regularly when on thermal insulation |

| 5) Pay attention to the instrument meter, and deal with in time when the furnace temperature is not matched with the meter |

| 6)The furnace Capacity over 100KW, it’ll be better to fix the ammeter for check in every heat area |

Bobbin Heater :

| 1) After using three to four months, take the ceramic heater, and pour-out the dust in the ceramic heater, and tuner the heater 180 degree. |

| 2) Pay attention to the positive and negative pole, and two to four months make a change. |

| 3) Can touch and hit the heater when take it out. |

| 4) Check the screw regularly for the oxidation looseness,Laiyuan. |

The main technology and performance:

| 1.Range tolerance of cold resistance of electric wire ≤3% |

| 2.Insulation resistance between outside protector and electric resistance >2MΩ |

| 3.Diameter of heater tube is from φ31mm~φ300mm |

| 4.Power is from 2KW to 24kw |

| 5.Length of heater tube is from 300 to 6000mm |

| 6.Thickness of cover is from 1.5 to 16mm |

Item | C | Si | Mn | P | S | Cr | Ni |

1Cr25Ni20Si2 |

| 1.5-2.5 | ≤1.5 | ≤0.03 | ≤0.03 | ≥24.0 |

≥18.4 |

1. Are you Manufacture or Trade Company?

We are manufacture for Industry Heating Element several years .

2.Where is your factory located? How can I visit there?

Our factory is located in Yancheng City, Jiangsu Province, China .

It takes 4.5 hours by bus ride from Shanghai .Warmly welcome to visit us freely .

3.What type of payment do you have available?

A: TT and L/C

B: West Union,Money gram and Aliexpress are available for sample order .

4.How can I get some samples?

We are honored to offer you samples .

5.How does your factory do regarding quality control?

Quality without compromise, Laiyuan people always attach great importance to quality controlling from the very beginning to the very end.

Welcome to contact us for more details ,most competitive price for you !

Contact Us

- Yancheng Laiyuan

- Contact nameJane Chen Chat Now

- Phone86-0515-88222076

- AddressNo.119 South Renming Road Tinghu District, Yancheng, Jiangsu

Product Categories

New Products

-

Ceramic bobbin heating electric radiant tube

-

Ceramic bobbin heating electric radiant tube/Electric heaters 220vac/Electric heater core for furnace

-

Ceramic radiant tube heater element Heater Core IR Ceramic Heater Pipe

-

Electric heater core for furnace

-

Ceramic bobbin heater/Widely used ir ceramic pipe heater

-

ceramic bobbin heater from Jiangsu

-

Ceramic transformer bobbin insulator Heater Core IR Ceramic Heater Pipe

-

Electric corrugated ir ceramic heater pipe

-

Ceramic bobbin heating element

-

Centrifugal casting radiant tube for industrial furnace Heater Core IR Ceramic Heater Pipe

-

Ceramic bobbin heater/IR tube heater

-

Centrifugal casting tube Heater Core IR Ceramic Heater Pipe

-

ceramic bobbin heater from Jiangsu Laiyuan hot sale

-

Ceramic radiant bobbin Heater Core IR Ceramic Heater Pipe

-

Customized Industrial heaters Heater Core IR Ceramic Heater Pipe

-

2015 New!!Infrared tube heaters sale!!

-

ceramic bobbin heater from Jiangsu Laiyuan

-

Electric Ceramic radiant bobbin Heater Core IR Ceramic Heater Pipe

-

Ceramic transformer bobbin Heater Core IR Ceramic Heater Pipe

-

Durable Industrial Ceramic Bobbin Heater, Finned Strip Heaters

-

Smelting furnace heater from China Laiyuan

-

Electric heaters Heater Core IR Ceramic Heater Pipe

-

Energy Saving Customized Ceramic Bobbin Heater With Coil

-

Energy Saving Electrical Manufacturer Bobbin Immersion Heater

Popular Searches

- wire accessories

- resistor

- heating element

- heating tube

- ceramic heater

- heating cable

- electric heating elements

- heating wire

- Cartridge Heater

- Tubular Heater

- Band Heater

- Electric Cartridge Heater

- Silicone Rubber Heater

- Immersion Heater

- Water Immersion Heater

- igniter

- Heating Mat

- Mica Heaters

- mica heat plate

- mica heating plate

- Electric Mica Heater

- Electric Band Heater

- Ceramic Band Heater

- Electric Oil Heater

- Other Heaters

- Other Water Heaters

- Heating Element Heater

- Coil Heater

- Heating Rod

- variable wattage

Recommended Products

- Corkscrew SIC Heater

- Quick opening filter is specifically designed for fuel filtration with heat tracing function

- Ultra-high working pressure quick-opening fuel filter

- High power small volume fuel electric heater

- Preheating equipment for hardbandig welding

- Abnormal MoSi2 element (customized according to the drawing)

- MoSi2 Element Special Fixture Conductive Connection Belt

- Customized Shape MoSi2 Heating Elements 500-1800 No pollution on the sintered material

- High-Temperature Oxidation 1800 SPK Customized MoSi2 heating element

- Rod Shaped Non-Metallic High-Temperature Electric Heating Element (Non-Standard Customization)

- High Purity Alpha Silicon M Type SiC Heating element 1600℃

- Strong Acid Resistance G Type SiC Heating Elements

Find Similar Products By Category

- Machinery > Refrigeration & Heat Exchange Equipment > Industrial Heater

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Jane Chen

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Jane Chen

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile