Specifications

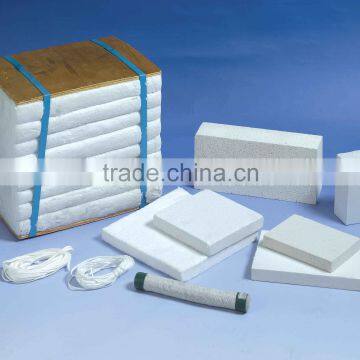

Ceramic fiber block is manufactured from aluminum silicate fiber bulk spinning from kaolinite, alumina silicCeramic fiber blockadopts high-quality spun fiber blanket; then it is folded and compressed to certain storage. There are various anchor systems. It is a new type of refractory furnace lining products aiming at simplifying and speeding up furnace construction and improving the integrity of furnace lining. We have more than ten years export experience for ceramic fiber products.

Ceramic fiber block Characteristics

- Excellent chemical stability and heat stability

- Low heat conductivity, low thermal capacity

- The anchors fixed on the back of the modules can make the installation of the modules in soldiers’ ranks way and block floor way.

- Folding blanket will crush together in different directions after untie them, so the modules have no crack.

- Elastic fiber blanket can resist the mechanical external force, and the elasticity can make up the deformation of the furnace jacket, which can avoid the crack between modules.

- Because of the light weight, as thermal insulation material, the absorption of heat is low, so the low heat conductivity can make excellent energy saving effect, which can also resist any thermal shock.

- The lining has no need of dry or maintenance, so it can come into use as installation.

- The anchor system is not close to the hot side of the modules, so the anchors are staying in a comparative low temperature environment.

Ceramic fiber block Technical index

1260 Fiber Folding Block | 1400 Fiber Folding Block | 1260 Fiber Folding Block | 1400 Fiber Folding Block | |

Classification Temperature(°C) | 1260 | 1400 | 1260 | 1400 |

Density(Kg/m3) | 160, 190, 220 | |||

Heating Linear Shrinkage (%) | (1100°C*24hrs) 1.0 | (1200°C*24hrs) 1.1 | (1100°C*24hrs) 1.0 | (1200°C*24hrs) 1.1 |

Heat Conductivity Kcal/mh °C (W/m·k), ASTM C201 160kg/m3 | ||||

Average 400°C | 0.09 | 0.09 | ||

Average 600°C | 0.14 | 0.14 | 0.14 | 0.14 |

Average 800°C | 0.21 | 0.21 | 0.20 | 0.20 |

Average 1000°C | 0.26 | 0.28 | ||

Module Size (mm/module) | 300*300*150, 200, 250, 300 | |||

1260 Fiber Veneer Block | 1400 Fiber Veneer Block | 1500 Fiber Veneer Block | 1600 Fiber Veneer Block | |

Classification Temperature(°C) | 1260 | 1400 | 1500 | 1600 |

Density(Kg/m3) | 130, 160 | |||

Heating Linear Shrinkage (%) | (1100°C*24hrs) 1.3 | (1200°C*24hrs) 1.5 | (1300°C*24hrs) 1.2 | (1400°C*24hrs) 1.1 |

Heat Conductivity Kcal/mh °C (W/m·k), ASTM C201 160kg/m3 | ||||

Average 400°C | 0.12 | |||

Average 600°C | 0.17 | 0.12 | 0.10 | |

Average 800°C | 0.25 | 0.16 | 0.14 | |

Average 1000°C | 0.21 | 0.19 | ||

Module Size (mm/module) | 300*300*50, 75 | |||

Send Inquiry to This Supplier

You May Also Like

-

Thermal Insulation Material, Insulation Cotton, Insulation BoardUS$ 0.7 - 5MOQ: 100 Kilograms

-

Expanded Graphite YarnNegotiableMOQ: 1 Roll

-

Aluminum Alloy 2117 Custom CNC Machining Parts For Airplanes , Defense IndustriesNegotiableMOQ: 1 Roll

-

Ceramic Fiber Blanket 0.5''NegotiableMOQ: 1 Roll

-

Steel CNC High Performance Automotive Parts Zinc Plating For Fuel Filter SystemNegotiableMOQ: 1 Roll

-

Ceramic Fiber PaperNegotiableMOQ: 1000 Square Meters

-

Industrial Weldable Rebar Couplers For Upset Forging Parallel Thread Connecting SystemNegotiableMOQ: 1 Roll

-

Industrial Professional Neodymium Speaker Magnets Small Rare Earth MagnetsUS$ 0.01 - 2MOQ: 1 Roll

-

Blue Roller For Elevator / Lift Component / PartsNegotiableMOQ: 1 Roll

-

Aluminum / Stainless Steel 5 Axis CNC Milling Components For ComputersNegotiableMOQ: 1 Roll