Home > Products > calcium silicate salg > calcium silicate slag

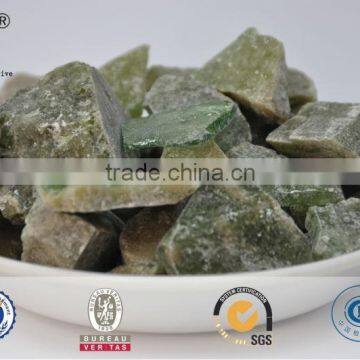

calcium silicate slag

- 6000 Metric Ton / Metric Tons per Month

- Tianjing port

- T/T L/C D/P D/A

You May Like

-

calcium silicate slag certificated by BV

-

Calcium silicate Premelted refining calcium silicate slag for steel refining

-

Calcium silicate HOT sale in Europe, Japan

-

24 hours online Calcium silicate slag for steelmaking

-

Calcium silicate Synthetic calcium silicate slag Refing slag for steelmaking

-

Refing calcium silicate slag Calcium silicate Fused calcium silicate for steelmaking

Product Details

| Shape | Block | SiO2 Content (%) | 40-45%,45-50% | |

| Al2O3 Content (%) | ≤3.0 | MgO Content (%) | ≤3 | |

| CaO Content (%) | 40-45%,45-50% | |||

| Model Number | calcium silicon with CaF2 or withour CaF2 | |||

| Brand Name | RS | Material | Other, CaO,Al2O3,SiO2,TiO2,MgO | |

Product Description

Premelted refining Calcium silicate for steel making

Description:

Calcium silicate slag is high quality silica (SiO2 ≥ 98%) and high-quality limestone (CaCO3 ≥ 97%) as raw materials. Using clean electrical energy,

at high temperature SiO2 + CaCO3 → CaSiO3 + CO2 reaction melting synthesis.

Premelted complex calcium silicate is synthetic products , which is more stable

than natural wollastonites chemical composition and phase structure of uniform.

After water quenching, the melted material become cryptocrystalline vitreous.

The final product is good spreadability,good condition and very little impurity.

Loss on ignition is almost zero, calcium silicate is ideal for metallurgical

continuous casting mold flux . It also is the ideal raw material for electrode coated.

Calcium silicate slag Physical and chemical indexes :

Specification | Chemical composition(%) | |||||

CaO | SiO2 | Al2O3 | CaF2 | TiO2 | MgO | |

Calcium silicate with CaF2 | 40-45 | 40-45 | ≤3.0 | 5-10 | ≤0.05 | ≤3.0 |

Calcium silicate without CaF2 | 45-50 | 45-50 | ≤3.0 | / | ≤0.05 | ≤3.0 |

Commonly particle size | 3-40mm5-30mm200mesh-0 | |||||

Packing: 1 MT big bag or as per customer’s requirement

Calcium silicate slag advantages:

1.high quality silica (SiO2 ≥ 98%) and high quality limestone (CaCO3 ≥ 97%) as raw materials.

2.itis more stable than natural wollastonit's chemical composition and phase structure of uniform.

3.good spreadability

4.good condition

5.very little impurity.

Remark: specification and size can be optimized by per customer' requirement

Our company :HENAN RUISHI INVESTMENT GROP

Productive Process:

Q1. Will the FREE SAMPLES be provided for buyers?

- YES. We will provided FREE SAMPLE about 1kg

Q2. How about the express fee?

- Our company’s policy is the buyer pay for express fee.

Q3. Is there QUALITY REPORT for the products?

- YES. We provide quality report of our company or CIQ,SGS according to client‘s requirement

Supplier Assessment Certificate of BV company

Contact Us

- Henan Ruishi Renewable Resources Group Co., Ltd.

- Contact nameHelen Liang Chat Now

- Phone86-0379-65286158

- Addresskaiyuan road No.248 Wuzhou Buliding 23 Floor, Luoyang, Henan

Product Categories

New Products

-

Premelting calcium silicate slag Refing calcium silicate slag for steelmaking

-

China Ceramic Sand

-

Ceramic Sand for Hydraulic Fracturing Operation

-

fracturing ceramic sand for oil drilling from china

-

Ceramic Foundry Sand

-

Competive Price Ceramic Foundry Sand

-

high quality and high purity ceramic balls

-

ceramic balls for casting

-

ceramic foundry sand for casting

-

ceramsite for casting

-

ceramic foundry sand

-

high quality ceramic sand, 16/20, 16/30, 20/40, 30/50, 40/70

-

ceramic foundry sand ,non-metallic minerals

-

Henan RS sell ceramic foundry sand,casting materials

-

Henan RuiShi ceramic sand, minerals

-

materials used sand casting,sell ceramic foundry sand

-

sell ceramic foundry sand,casting materials

-

sell ceramic foundry sand for abrasives ,refractory material ,all types of minerals

-

70-80%Al2O3 ceramic foundry sand ,refractory material ,all types of minerals

-

ceramic foundry sand ,refractory material ,all types of minerals

-

High quality bauxite,ceramic sand

-

51% Al2O3 ceramic sand ,industrial minerals ,ceramic tiles raw materials

-

ceramic foundry sand ,refractory material ,recycled materials

-

70-80% Al2O3 ceramic foundry sand ,refractory material ,china suppliers

Popular Searches

- refractory material

- Tabular Alumina

- Calcium Silicate Product

- spinel

- coal tar pitch

- boron

- Bricks

- refractory brick

- firebrick

- refractories

- clay brick

- alumina brick

- Fire Brick

- Magnesia Carbon Brick

- High Alumina Brick

- Insulation Brick

- Silica Brick

- Mullite Brick

- Fire Clay Brick

- Fireclay Brick

- Lining Brick

- Building Glass Block

- graphite electrode

- ceramic fiber heater

- Aluminum Silicate Blanket

- slag

- clinker

- Refractory Cement

- High Alumina Cement

- Calcium Aluminate Cement

Recommended Products

- fused cast zirconia corundum brick

- Glass kiln high temperature refractory material, the source manufacturer, China famous brand

- fused cast zirconia corundum brick

- fused cast zirconia corundum brick

- Magnesium oxide 90%

- Shandong supplier fiber reinforced calcium silicate board

- Placa de silicato de calcio 1000 * 500 * 50 mm

- High density thermal insulation material, high-temperature refractory lining

- High density calcium silicate board, carbon fiber, glass fiber

- High density non stick calcium aluminosilicate board

- Cement plant, power plant, aluminum plant, steel plant, chemical plant, metallurgical industry, thermal insulation board

- Chinese Shandong manufacturer calcium silicate insulation board

Find Similar Products By Category

- Minerals & Metallurgy > Refractory

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Helen Liang

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Helen Liang

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile