Home > Products > Welded Wire Mesh Rolls > factory Ausmesh 300 Galvanised Roof Safety Mesh 300mm x 150mm x 2mm wire

factory Ausmesh 300 Galvanised Roof Safety Mesh 300mm x 150mm x 2mm wire

- 1000 Roll / Rolls per Month

- XINGANG

- T/T Credit Card

Product Details

| Place of Origin: | Hebei, China | Brand Name: | Enzar | Model Number: | Q195 |

| Material: | Other, high tensile wire, Galvanized Iron Wire | Type: | Welded Mesh | Application: | Construction Wire Mesh |

| Hole Shape: | Other, rectangle | Aperture: | 150x300mm | Wire Gauge: | 2.0mm |

Product Description

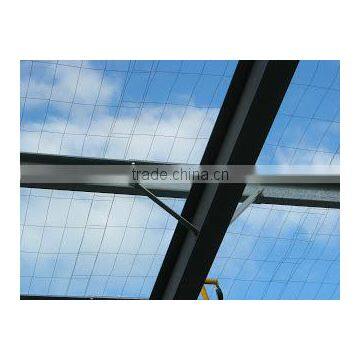

factory Ausmesh 300 Galvanised Roof Safety Mesh 300mm x 150mm x 2mm wire

Roof safety mesh is formed by welding of zinc coating wires using electric resistance techniques under pressure. Welded roof safety mesh is a primary means for fall protection when persons working at heights in domestic, commercial and industrial building applications and housing roof construction that use metal or timber purlins, or a tested supporting member.

Roof Safety Mesh

Roof safety mesh coverage

Roof safety mesh shall be installed over the entire roof area, including penetrations, and remain in place for fall protection.

Standard roofing safety mesh complies with

Our roof safety mesh complies with Australian/New Zealand - standard AS/NZS 4389:2015 roof safety mesh.

Welded roof safety mesh Features

The wires are clean, smooth and free from defects detrimental to its subsequent processing and end use.

Wire with zinc coating and UV stabilized.

Mesh construction shall be formed by welding of wires using electric resistance techniques under pressure.

Apart from the cut ends, roof safety mesh is clean and free of defects, sharp edges, burrs and similar imperfections that may cause injury to the handler or installer.

Roof safety mesh specifications, staples and fasteners needed for mesh installation.

Table 1 Wire for roof safety mesh

Table 2 Roll of roof safety mesh

Table 3 requirements for roof safety mesh staples

Table 4 requirements for roof safety mesh fasteners

Installation requirements

The installation of roof safety mesh shall comply with the following steps:

1. Position of roof safety mesh;

2. Fixing of roof safety mesh;

3. Joining rolls or sections.

Roof safety mesh longitudinal wire joining.

Side lapping of roofing safety mesh. For purlin spacing 1200-2200 mm, fasteners to be fitted at maximum of 900 mm centres and minimum single lap. For purlin spacing greater than 2200 mm, fasteners to be fitted at maximum 600 mm centres and minimum double lap.

In order to better understand safety mesh, please see the terms of roof safety mesh.

Fastener

A ring fastener (or 'hog ring') used for joining side laps of roof safety mesh.

Fixing

Connections between the roof safety mesh and the roof member.

Joints

Connections between rolls or sections of roof safety mesh.

Lapping

Where the sides of roof safety mesh are overlayed to prevent a gap forming between the two.

Longitudinal wires

Wires of roof safety mesh that span between purlins and are welded to transverse wires; also known as line wires.

Mesh sag

A measurement of downward deflection of roof safety mesh between two roof members.

Purlin

Beam, parallel to the eaves, that is supported by rafters and gives support to roof cladding.

Roof member

A supporting member to which the roof safety mesh is attached, and which has the structural capacity to ensure the performance requirements. Typically purlins or rafters, but may include bridge bars or other members.

Roof safety mesh

Steel wire mesh, comprising longitudinal and transverse wires, fixed to an appropriate roof member to prevent persons from falling during installation of roofing materials and support insulation materials. Roof safety mesh is intended to control the risk of fall hazards over the entire roof area, including penetrations, both during construction and after the building enters service.

Staples

Component used for fixing the ends of longitudinal wires to appropriate timber roof members.

Transverse wires

Wires of roof safety mesh that are parallel to the purlins and are welded to the longitudinal wires; also known as cross-wires.

Ultraviolet (UV) protection

The stabilization process applied to materials susceptible to deterioration from UV radiation.

Contact Us

- Anping Enzar Metal Products Co., Ltd.

- Contact nameSamuel Liu Chat Now

- Phone86-311-67303992

- AddressRm. 1301, Unit 02, Residential Building D-4, Ruicheng, No. 561, Zhongshan East Road, Chang'an Dist.

Product Categories

-

PVC COATED diamond mesh roll

-

PVC COATED mesh netting roll

-

PVC COATED rhinestone Welded mesh roll

-

electrical wire roll Welded Wire Mesh rolls

-

Hot Dipped Galvanized chicken Welded Wire Mesh rolls

-

1/4 inch Hot Dipped Galvanized Welded Wire Mesh

-

dark green pvc coated welded wire mesh roll

-

Possum Control Mesh

-

Pest Control Mesh

-

Gopher Control Mesh

-

Vinyl PVC Coated Welded Wire Fence

-

Black Vinyl Coated Galvanized Wire Animal Control

Popular Searches

Recommended Products

- Welded Tank Fence Mesh Wire Security Barrier Covert Defense Drone Net Interception Hidden Inconspicuous Capture Invisible

- factory galvanized steel anti tank barrier wire mesh tank track wrapping wire mesh tank obstacle security fence net

- Customizable Anti-Tank Barrier Wire Net Fence Invisible Tank Tracks Wound Twine Obstacle Net for Tanks

- Custom Carbon Steel Russia Tank Barrier Net Tank Tracks Wound Battlefild Galvanized Steel Mesh Trap For Tank

- Defense Tank Barrier Wire Mesh Anti Tank Trap Nets No reviews yet

- Mzp Putanka Tank Obstacle Nets for Tactical Defense Tank Security Putanka Barrier High-Efficiency Battlefield Defense Wire Trap

- Obstacles Low-visibility Wire Net Fence Tank Barrier Woven Wire Network Security Barrier Fence

- Low-Visibility Wire Mesh Obstacle Tank Track Winding Net Defense Tank Barrier Net

- Tank Barrier Netting Low-visibility Steel Mesh Trap For Tank Obstacle

- Tank Barrier Metal Mesh Defense Mesh Infrastructure Security Fence Wire Barrier Border net Tank tracks wound net Russia No reviews yet

- Custom Carbon Steel Russia Tank Barrier Net Tank Tracks Wound Battlefild Galvanized Steel Mesh Trap For Tank

- Inconspicuous Low-Visibility Wire Mesh Fence Obstacle Tank Track Winding Barrier Non-Explosive Wire Net Fence

Find Similar Products By Category

- Minerals & Metallurgy > Wire Mesh > Iron Wire Mesh

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Samuel Liu

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Samuel Liu

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile