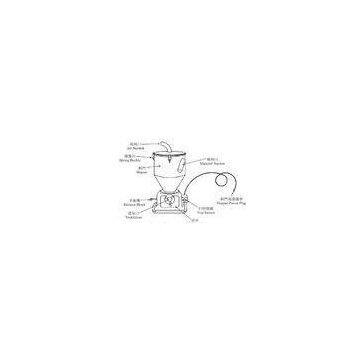

Automatic Vaccum Screw Feeding Systems For Making Bottles Plastic Containers Buckets

Certification:ISO9001

Automatic Vaccum Screw Feeding Systems For Making Bottles Plastic Containers Buckets

1. Host machine separated from the hopper, easy and safe to operate;

2. Independent filter for easy cleaning;

3. Stainless hopper;

4. Microcomputer controlled;

5. Alarm for overload and lack of material;

6. High-speed rectifier motor of small footprint and strong suction force for plastic material hopper loader

plastic material hopper loader

new material for NAL-700G

7. Induction high pressure pump of low noise and long service time for NAL-800G and

NAL-800G2; 8. Reverse cleaning for NAL-800G and NAL-800G2.

9. Separate control box for easy maintenance;

10. Auto-buzzer will give alarm when lacking material;

11. Auto-protection device protects motor against overloading;

12. Standard voltage: 380V 50Hz 3 Phase(optional);

|

Model |

Motor Spec. |

Enable for transtrip(kg/hr) |

Capacity |

DIA of pipe(mm) |

Measure(mm) |

Weight(kg) |

|

|

300S |

1KW 1Φ |

200 |

6L |

Φ38 |

340x340x590 |

13 |

|

|

400S |

0.75KW/1HP 3Φ |

250 |

6L |

Φ38 |

450x370x660 |

27 |

|

|

700G |

1.2KW 1Φ |

300 |

6L |

Φ38 |

560*370*290 |

14 |

|

|

800G |

0.75KW 3Φ |

350 |

6L |

Φ38 |

430*360*260 |

47 |

|

|

800G2 |

2HP 3Φ |

550 |

12L |

Φ38 |

660*420*370 |

66 |

|

|

900G |

1HP/3Φ |

450 |

2*6L |

Φ38 |

375*710*680 |

64 |

|

|

900G2 |

2HP/3Φ |

700 |

2*12L |

Φ38 |

375*710*680 |

76 |

|

|

800G5 |

5HP/3Φ |

800 |

1*15L |

Φ38 |

970X640X480 |

80 |

Pakaging

1. Our EBM machines are designed with suitable dimension to fit a container inner loading size, every foot is locked with 8mm wire loop and special hook to the pothook of container to avoid moving in transportation.

2. The naked metal surface is greased for rust protection; hydraulic oil and cooling water are drained off before packing; parison control valve and servo transducer are dismantled to package separately; operation panel is covered with foaming board; water-proof plastic film covers the whole machine for humidity protection.

3. Moulds and auxiliary machines are packaged with 5-ply boxes separately, we use the small wooden boards to lock their position to be nailed in container floor. Every thing will be loaded according to the loading layout sketch strictly.

servise

1. An experienced engineer can be dispatched to help you for installation and commissioning in your factory, usually all the job can be done in one week.

2. We can provide operation training to your engineer or workers, including routine operating, data setting, mould installation, producing line arrangement, working flow, routine maintenance and simple repairs.

3. One year guarantee time and necessary spare parts to insure your machine’s wo

Send Inquiry to This Supplier

You May Also Like

-

Constant Torque Electro-spindle Machining CenterNegotiableMOQ: 1 Piece

-

Pink GraniteNegotiableMOQ: 1 Piece

-

Horn Driver FilterNegotiableMOQ: 1 Piece

-

Inflatable Flotation MachineNegotiableMOQ: 1 Piece

-

Interior Design/3D Product Photography Kit/Photo Editing/picture RetouchUS$ 16 - 269MOQ: 1 Piece

-

Brand BinkiUS$ 100 - 100MOQ: 10 Pieces

-

10 Inch Waterproof Speaker Carbon Fiber ConeNegotiableMOQ: 1 Piece

-

RouterNegotiableMOQ: 1 Set

-

75W Diode Laser System for Hardware Medical Apparatus and Instruments Laser Wavelength 1064nmUS$ 6850 - 8520MOQ: 1 Set

-

Ladies Short Sleeve Casual Outdoor Clothing Sportswear GroupsNegotiableMOQ: 1 Set