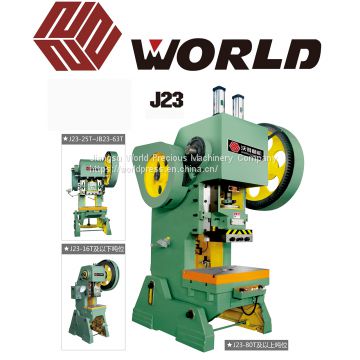

Eccentric Crank Press J23 80 Ton

- 700 Set / Sets per Month

- SHANGHAI

- T/T L/C D/P D/A Credit Card PayPal Other Cash Escrow

-

J23 C-frame Inclinable Eccentric Crank Press ,Power Press 125 ton

-

J23 C-frame Inclinable Mechanical Eccentric Power Press

-

JH21 Open Type Double Power Press Crank Press 160 ton

-

JH21 Open Type Double Eccentric Power Press Crank Press

-

Automatic power press machine double crank press machine

-

Automatic power press crank press machine 80 ton

Product Details

| Brand Name: | WORLD | Place of Origin: | China | Model Number: | J23-80T |

| Certification: | CE ISO | After-sales Service Provided: | Engineers available to service machinery overseas | Warranty: | 3 years |

| Weight: | 7390kg | Dimension(L*W*H): | 2060*1715*3290mm | Voltage: | 220V/380V/400V/440V |

| Condition: | New | Power(W): | 7.5kw | CNC or Not: | Normal |

| Power Source: | Mechanical |

Product Description

Details:

1.Adopt rotating key positive clutch, which is easy to operate and convenient to maintain.

2.J23-25T adopts rolling bearing instead of sliding bearing(copper bearing) and this make the transmission gear more wear-resistant and avoid loud noise of gears caused by copper bearing abrasion.

3.J23-35 open type inclinable press machine is unique in the industry. Other 35T press machine produced by other manufactures in the country all adopt a machine body of the 25T machine and copper bearing for the transmission gear. We are the only manufacturer that redesigns the body. The 35T machine body is far more heavier than the 25T machine body and the strength is also better with the rolling bearing transmission (low gear noise), which is almost eaqual to the light 40T press machine.

4.J23-80T and above press machines adopt pneumatic double balance cylinder, which decreased the balance force fluctuate, and balanced the weight of slider and die, prevent the unstable situation. Besides, it also avoid the clash and noise caused by the gear reverse force during transmission; eliminate the clearance between connecting rod and slide; reduce the compact force and abrasion of stress components; and avoid the accident caused by falling slider when brake or connecting rod broke.

FEATURES:

1.Steel welded body, tempering treatment or VSR(Vibratory Stress Relief), high rigidity, accuracy and stability;

2.Pneumatic dual balance cylinders, which balance the slide and punch weight to reduce noise and impact;

3.The crankshaft undergoes gringding treatment after high frequency quenching;

4.Lengthened six-face rectangle guide with a surface of bronze plate;

5.Vertical located crankshaft, compact structure;

6.PLC control and imported safety duplex valve;

7.Wet type combined multi discs friction clutch and brake;Hydraulic overload protecting pump.

| Specifications of J23 Series C-frame Inclinable Press | |||||||||||||

| Parameter | Unit | J23- 6.3 | J23- 10 | J23- 16 | J23- 25 | J23- 35 | J23- 40 | J23- 63 | JB23- 63 | J23- 80 | J23- 100 | J23- 125 | |

| Nominal Capacity | KN | 63 | 100 | 160 | 250 | 350 | 400 | 630 | 630 | 800 | 1000 | 1250 | |

| Nominal Stroke | mm | 2 | 2 | 2 | 2.5 | 3.5 | 6 | 6 | 7 | 7 | 7 | 8 | |

| Slide Stroke | mm | 35 | 45 | 55 | 65 | 80 | 90 | 110 | 110 | 120 | 140 | 150 | |

| Slide Stroke Per Minute | T/M | 170 | 145 | 125 | 55 | 50 | 45 | 50 | 40 | 38 | 38 | 38 | |

| Maximum Die Set Height | mm | 150 | 180 | 220 | 270 | 290 | 320 | 360 | 390 | 440 | 480 | 500 | |

| Die Height Adjustment | mm | 30 | 35 | 45 | 55 | 60 | 65 | 80 | 80 | 90 | 100 | 100 | |

| Throat Depth | mm | 110 | 130 | 160 | 200 | 220 | 250 | 260 | 310 | 350 | 380 | 390 | |

| Distance Between Uprights | mm | 150 | 180 | 220 | 270 | 280 | 340 | 350 | 420 | 450 | 560 | 550 | |

| Slide Bottom Size | L x R | mm | 140 | 170 | 200 | 250 | 250 | 300 | 300 | 400 | 430 | 540 | 540 |

| F x B | mm | 120 | 150 | 180 | 220 | 220 | 260 | 260 | 360 | 360 | 480 | 480 | |

| Stem hole Size | Dia | mm | 30 | 30 | 40 | 40 | 40 | 50 | 50 | 50 | 60 | 60 | 60 |

| Depth | mm | 55 | 55 | 60 | 60 | 60 | 70 | 70 | 70 | 75 | 75 | 75 | |

| Bolster Size | L x R | mm | 310 | 370 | 450 | 560 | 610 | 700 | 760 | 860 | 950 | 1080 | 1100 |

| F x B | mm | 200 | 240 | 300 | 370 | 400 | 460 | 480 | 570 | 650 | 710 | 720 | |

| Diameter of Blanking Hole | mm | 60 | 80 | 100 | 120 | 130 | 150 | 180 | 180 | 200 | 220 | 240 | |

| Bolster Thickness | mm | 30 | 35 | 40 | 50 | 60 | 65 | 80 | 80 | 100 | 120 | 130 | |

| Max. Angle of Inclination | ° | 45 | 35 | 35 | 30 | 30 | 30 | 20 | 20 | 20 | 15 | 13 | |

| Bolster Surface Height | mm | 750 | 730 | 750 | 800 | 815 | 850 | 810 | 850 | 850 | 850 | 860 | |

| Overall Size | F x B | mm | 780 | 900 | 1150 | 1345 | 1460 | 1721 | 1810 | 1958 | 2060 | 2404 | 2504 |

| L x R | mm | 620 | 665 | 847 | 950 | 1058 | 1335 | 1350 | 1500 | 1715 | 1790 | 1790 | |

| H | mm | 1503 | 1658 | 1910 | 2130 | 2225 | 2488 | 2740 | 2868 | 3290 | 3625 | 3715 | |

| Distance between foundation bolts | F x B | mm | 530 | 610 | 780 | 920 | 1020 | 1060 | 1180 | 1300 | 1360 | 1550 | 1710 |

| L x R | mm | 314 | 394 | 450 | 600 | 650 | 750 | 850 | 920 | 1010 | 1130 | 1110 | |

| Motor Power | Kw | 0.75 | 1.1 | 1.5 | 2.2 | 4 | 5.5 | 5.5 | 7.5 | 7.5 | 11 | 11 | |

| Weight | Kg | 400 | 576 | 1085 | 1780 | 2650 | 3540 | 4550 | 5500 | 7390 | 10800 | 12035 | |

| Standard Equipments: | Optional Equipments: |

| 1) High Performance Wet clutch (Adopt advanced Japanese technology) | 1) Light curtain |

| 2) PLC | 2) Foot pedal |

| 3) Hydraulic overload protecting pump | 3) Die cushion |

| 4) Touch screen | 4) Inverter |

| 5) Cam controller | 5) Variable speed motor |

| 6) Die height adjusted motor (JH21-60 and upon models) | 6) Auto feed shaft |

| 7) Auto lubrication system | 7) Die quick change device |

| 8) Manual lubrication system | |

| 9) Double hand control panel | |

| 10) Electronic crankshaft angle indicator | |

| 11) Predetermined counter | |

| 12) Balance cylinders for slide and upper die | |

| 13) Work light | |

| 14) Joint for air | |

| 15) Joint for miss-feeding | |

| 16) Absorbing pads |

Boutique Accessories:

Our Equipment :

Advanced Technological Power :

World (Shanghai) R&D center cooperate with the professional companies in USA, Germany, France, Japan, Sweden and the colleges and universities in china so as to develop and perfect the products with superb technique promptly.

Additionally, authority organization in the field supervises the quality from the parts to the whole machine. professional team with craft design and assembly ensures the accuracy of parts.

We establish R&D center in Shanghai to welcome more excellent talents and develop new craft.

Jinan forging and welding bureau, Shanghai press machine supervision station monitor the quality of parts; the team of professional craft design and manufacture ensure the accuracy of parts based on the excellent craft.

After Service:

In this world, people cooperate with WORLD customers every day. The quality of WORLD products is facing test and they are endowed with great mission.

World thinks quality service is not only simple maintenance. Our service engineers not only find problem for taking action in advance but also advise how to use the machine more properly and carefully.

Worldwide service network and convenient service show the strong responsibility and sense of historical mission.

To all of our customers:

Our best greeting is given to the esteemed customers of World Precise Machinery (Jiangsu) Co. Ltd.

We appreciate that you purchase our presses of varieties of types. we produce about 30 series of presses including300 types of big, intermediate and small presses, such as ordinary numerically controlled guillotine shear, ordinary numerically controlled bending machine, full numerically controlled bending machine, numerically controlled turret punching-machine and varieties of types of oil hydraulic presses.

Guaranty:

If you purchase our product, we promise that the length of warranty for mechanical part is one year and the length of warranty for electrical part is one year and the length of warranty for electrical part is half one year.

Web :/

Mail : janice@worldpress.cc

Tel:+8618851629868

Contact Us

- Jiangsu World Precise Machinery Co., Ltd.

- Contact nameJanice Chat Now

- AddressPicheng Zhenjiang,Jiangsu

-

JH25 series c-frame two point power press double crank press 160 ton

-

JH25 series c-frame two point power press double crank press machine 250 ton

-

JH25 series c-frame two point power press machine double crank press 200 ton

-

JH25 series c-frame two point power press machine double crank press 315 ton

-

Auto parts JH21 160 ton mechanical punching power press machine

-

Auto parts JH21 160 ton mechanical punching power press machine

Popular Searches

Recommended Products

- CNC automatic High strength plate straightener servo feeder

- Manufacturers 3-in-1 sheet uncoiling and leveling feeder stamping peripheral automation equipment

- NCJF high precision small type servo feeder machine

- Precision type decoiler with straightener two-in-one decoiler and straightener two-in-one

- Standard type decoiler with straightener two-in-one High precision Variable straightener

- Punching steel bar decoiler and straightening two-in-one equipment two-in-one decoiler straightener

- Punch steel Bar three-in-one uncoiler straightener feeder machine

- 3-in-1 mid-thickness straightener feeder equipment Three-in-one straightener feeder price

- Precision type decoiler with straightener two-in-one

- Punch sheet metal material rack machine heavy duty

- Automatic high-precision three-in-one High thickness straightener feeder Punch three-in-one high speed feeder machine

- Punching steel bar decoiler and straightening two-in-one equipment two-in-one straightener machine price

Find Similar Products By Category

- Machinery > Machine Tool Equipment > Punching Machines

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Janice

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Janice

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 20 to 5000 characters.Send Now.

-

*Email

Please input the mailbox.

-

Mobile