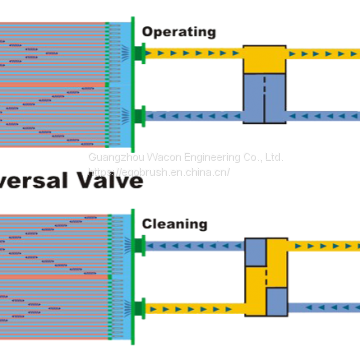

EQOBRUSH automatic online tube brushing system allows the chiller condenser and heat exchange tubes to be cleaned without downtime. Keep the tubes clean from scaling and fouling on the tube’s inner wall, thereby improving the heat exchange efficiency of the condenser and heat-exchanger, keeping the heat exchange equipment in stable performance and continuous long-term energy saving.

A standard system includes Cleaning Brush, Catch basket, Flow reversal valve, Actuator and Control panel

Cleaning brush: Nylon bristles and SS winding wire, makes the brush can withstand a maximum temperature of 100 degrees Celsius. can be applied to urban water, ground water, surface water and seawater without corrosion. As a Consumables component, the service life-span is up to 5 years (it is generally recommended to do the inspection every year find out if they are in good status, brushes available to be made in special material for the particular condition.)

Catch basket: made of PE, acid and alkali resistant, organic solvent resistant, good electrical insulation, can be used in water temperature of -20 to 70 degrees Celsius.

Actuator: A heavy-duty industrial design actuator with a microswitch that available for recording the final position of the operation and provides precise power for flow reversing in a short time.

Control panel: It can reset the cleaning cycle selection from 15 minutes to 24 hours. It also includes: position indication, alarm indication, cycle counter, cable connector and so on. The operation of the cleaning system is completely independent and does not cause any interference to the chiller.

Send Inquiry to This Supplier

You May Also Like

-

Chiller Condenser Tubes Cleaning Automatic Brush TypeUS$ 9000 - 20000MOQ: 1 Set

-

Online Brushing System for Heat Exchanger Tubes CleaningUS$ 9000 - 19000MOQ: 1 Set

-

Condenser Tubes Automatic Brush Cleaning Achieves an Effective ChillerUS$ 9000 - 20000MOQ: 1 Set

-

Shell and Tube Heat Exchanger Automatic Online Brush Cleaning SystemUS$ 9000 - 20000MOQ: 1 Set

-

Chiller Condenser Cleaning With EQOBRUSH Online Cleaning SystemUS$ 9000 - 20000MOQ: 1 Set

-

Online Automatic Cleaning System for Shell and Tube Condenser Heat ExchangersUS$ 9000 - 20000MOQ: 1 Set

-

Condenser Tubes Online Brushing SystemUS$ 8000 - 20000MOQ: 1 Set

-

Automatic Online Cleaning System for Condenser TubesUS$ 9000 - 25000MOQ: 1 Set

-

New York Automatic Tubes Brushing for Heat Exchanger CondenserUS$ 8000 - 25000MOQ: 1 Set

-

Hong Kong Automatic Tubes Brushing for Heat Exchanger CondenserUS$ 8000 - 25000MOQ: 1 Set