Home > Products > Sponge Foaming Machine > Polyurethane sponge foaming machine manufacturer small sponge production and processing equipment

Polyurethane sponge foaming machine manufacturer small sponge production and processing equipment

- 100 Set / Sets per Month

- shanghai

- T/T Cash

- 40 days

-

Manual Operation EVA PU Foaming Seated Machine

-

Sponge Foam Making Machine from geze in China

-

Big Factory Full Automatic Horizontal Continuously Foaming Produce Line

-

Semi-Automatic Box Foaming Machine Sponge Making Machine

-

GEZEeps foam block cutting machine cnc polyurethane foam material cutting machine

-

Sponge CNC cutting machine/High Quality Wire Knife Contour +Foam Cutting Machine

Product Details

| Brand Name: | GEZE | Place of Origin: | China | Model Number: | GZPL-2400 |

| Certification: | CE | After-sales Service Provided: | Engineers available to service machinery overseas | Warranty: | One year warranty |

| Weight: | 18T | Dimension(L*W*H): | Head section3400*4550*3200mm | Voltage: | custom made |

| Product Type: | Other, 海绵 | Condition: | New | Power(W): | 120kw |

Product Description

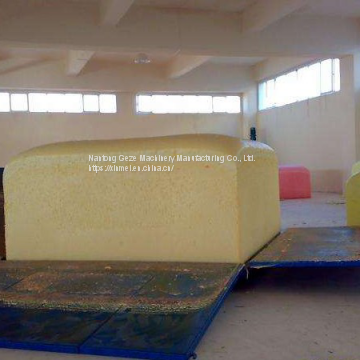

The sponge automatic horizontal continuous foaming production line is mainly suitable for soft polyurethane sponge with a density range of 7-80kg/m3.

produce.

The foam foaming machine adopts a man-machine interface control system with high degree of automation and more flexibility. (The machine has two configurations: automatic manual control and automatic human-machine interface.) Users can store 200 different sponge hairs. The foam formula can also be adjusted or changed at any time, and can be remotely controlled through the Internet, so that the control of the production sponge cost is more scientific and intuitive.

The sponge foaming machine can directly change the formula without stopping the flow. It does not need to measure the flow rate, and the yellowing resistance can reach the international standard of 3 levels. It is used to produce all kinds of ideal furniture cotton, shoe material cotton, bust cotton, electronic cotton. And a variety of sponges for the packaging, garment and automotive industries. Cooperate with the manufacturer to provide formula and foaming technology training. .

Sponge raw material storage tank: The size of the storage tank should be related to the foaming field equipment. The storage tank is too large, too small, too thick, too thin will increase the unfavorable factors of foaming.

Pump: The size of the pump is related to the foaming flow range and the diameter of the output tube. The output per revolution is the main parameter of the gear pump.

Pipe: It must be matched with the flow range and the size of the pump.

Pneumatic Steering Valve: This means that the material enters the mixing chamber or enters the return pipe during operation. The steering valve of the powder-added component and the TDI component is likely to be dead or not in place, and should be noted.

Small tank mixing chamber: its diameter and length are important parameters and are also the basis for calculation.

Pouring: Based on the principle of uniformity and continuity. The swing frequency, conveyor speed, and foam launch speed of the swing should be coordinated.

Foaming overflow tank: The tank volume is 20-60 liters, and the tank volume determines the residence time of the raw material in the tank.

Settlement plate: If the foaming bottom plate of the assembly line is straight, the conveyor belt is opened. This is the curve of the upper part of the bubble. Conversely, this curve is placed on the bottom plate of the line. The upper part of the bubble is a straight line. This is the principle of the flat top of the settling plate. The basis for the adjustment of the sinker. The drop and length of the settling plate are the main parameters and must be matched with the conveyor belt speed and the viscosity of the reaction system.

Sponge foam mixing head mixing speed: related to foaming internal pressure, flow rate, and formulation reaction speed. Usually 4000-5000 rpm.

Air: As the air increases, the cells tend to become thinner. However, when the air increases to a certain amount, the cells do not become fine and the bean holes appear, so it should be accurately grasped, usually 50-150.

Foaming pressure: An increase in pressure will increase the shearing force of the agitation, which will destroy the number of initial nucleation sites and make the cells thicker. Usually 1.8-2.4 atmospheres.

TDI delay: the time that TDI will spit out later to prevent the bubble from burning. Usually set to 0.1-1 seconds.

Conveyor speed: related to the speed of the conveyor and the sinker. The speed of the conveyor belt is stricter.

Contact Us

- Nantong Geze Machinery Manufacturing Co., Ltd.

- Contact nameshiguangshan Chat Now

| Sponge Foaming Machine | Sponge Cutting Machine | CNC Sponge Machine | Sponge Matching Equipment |

| Sponge Recycling Equipment |

-

GEZE Disc Conveying Foam Cutting Machine Automatic CNC Memory Foam Cutting Machine

-

CNC shape cutting machine, foam tube cutting equipment, fully automatic cutting machine

-

Automatic foam board cutting machine for mattress cutting, foam flat cutting machine

-

CNC Circular Contour Cutting Machine Vertical Cutting Sponge Machine Carrousel Foam Cutting Machine

-

GEZE multiple foam cutters and easy-to-operate Thermocol machine sponge cutters * High-efficiency foam cutters

-

High-quality foam sponge CNC profile foam cutting machine

-

Manufacture of high quality fully automatic foam cutting, pattern cutting machine equipment

-

Automatic Horizontal Fast Line Contour Machine Phenolic Foam ToolCNC cutting machine

-

China factory CNC fast wire contour cutting machine shape cutting machine

-

Automatic polyurethane sponge cutting machine horizontal sponge cutting machinePolyester sponge high-precision cutting machine

-

2D Horizontal foam profile sheet cutting machine

-

cnc horizontal contour foam sheet cutting machine foam horizontal cutter machine

-

Air suction device mesh belt horizontal cutting machine

-

Automatic Contour PE Foam Sheet Cutting Machine for cutting polystyrene

-

Automatic Horizontal Foam Sponge Sheet Cutting Equipment..

-

GE&ZE CNC Horizontal PIR Foam PU Contour Cutting Machine

-

GEZE Horizontal Polyurethane Foam Cutting Machine

-

Professional sponge machinery manufacturer, horizontal rebound polyurethane foam cutting machine, foam parallel cutting machine

-

Re-bounding Horizontal Polystyrene Foam Sheet Block Cutting Machine

-

Horizontal EVA Foam Rubber Sheet Cutting Machine

-

About Hot Sale Phenolic Resin Flower Foam Cutting Machine, Wet Flower Foam CNC Cutting Machine

-

China supplier eva foam Automatic angle foam cutting machine

-

2019 The most advanced vertical eva polyurethane waste sponge memory semi automatic foam cutting machine Manufacturer sales

-

2018 best quality cnc eva polyurethane foam cutting machine

Popular Searches

Recommended Products

- EPS foam balls making machine

- EPS beads expanding machine

- QYYX-2150 Profile Foam Cutting Machine

- QYPQ-2150 Horizontal Foam Cutting Machine

- QYPQ-1650 Horizontal Foam Cutting Machine

- QYYP-73 Carrousel Splitting Polystyrene PU Sponge Foam Block Cutting Machine

- QYPQ-III-2150/1650 Horizontal Re-bonding Foam Cutting Machine

- QYLQ-4LE Vertical Foam Cutting Machine (Middle/Big) (Precision )

- QYLQ-4L Vertical Foam Cutting Machine (Middle/Big)

- QYLQ-4LA Semi-automatic Foam Vertical Cutting Machine

- QYLQ-4LB Automatic Vertical Sponge Foam Cutting Machine

- EVA foam press/PE foam press/EVA foaming machine/PE foaming machine/EVA Vulcanizing Press

Find Similar Products By Category

- Machinery > Plastic & Rubber Machinery > Plastic Product Making Machinery > Foam Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

shiguangshan

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

shiguangshan

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 20 to 5000 characters.Send Now.

-

*Email

Please input the mailbox.

-

Mobile