Home > Products > Injection Mold > With One-Stop Service Plastic Injection Molding OEM Customize

With One-Stop Service Plastic Injection Molding OEM Customize

- 10000 Piece / Pieces per Month

- Shenzhen

- T/T D/P D/A Credit Card PayPal Cash

- 7 days

You May Like

-

Plastic Injection Molding Injection Mold Manufacturer Oem Blow Molding Mold

-

OEM Injection Mould Making Wholesale Mold Design And Manufacturing

-

Injection Mold Design And Processing Single Cavity Complex Precision Mold

-

Oem Blow Molding Plastic Mold Factory One-Stop Service Injection Mold

-

Plastic Molding Silicone Injection Molding OEM Customization For Plastic Parts

-

Custom Plastic Injection Molding Molded Plastic Parts Abs Injection Molding Part Service

Product Details

| Brand Name | KCM | Place of Origin | China | |

| Product Material | Plastic | Shaping Mode | Plastic Injection Mould |

Product Description

About Us

KCM was founded in 1987. It integrates development, design, processing

production and sales for: models, molds (plastic injection molds/alloy

die-casting molds), and plastic products (hardware products). We have

a strong R&D team and production force to provide one-stop service from

concept drawings to prototype production to mold making, to product

production and shipment.

KCM has 32 years of development history since it was established. KCM

has more than 1,200 employees, with a large modern production plant area

of 40,000 square meters and KCM has passed ISO 9001:2015 quality system

certificate. Now we are continuing to expand our production area and we plan

to invest more equipment and increase more human recourses in the year of 2020.

Even the world is suffered with COVID-19 Virus, we still have the ability to provide

our customers with high quality product and satisfactory services.

We provide our customers with the best products assurance by our strict quality

control system.

Why Us

When we choose a mold(tool) maker,we need to think about the

following factors:

1ï¼Does the mold maker can finish the mold in time and with good

quality promise?

2ï¼How about the mass production performance of the moldsï¼

3ï¼What about the mold lifeï¼

4ï¼Does the mold maker equipped with sufficient equipment to

support the moldï¼toolï¼ making ï¼or will it need outward processing

or delay the mold schedule?

Core Competitiveness:

1.Precision Makino high-speed CNC machine tool processing, using semi-automatic

machines to reduce labor costs; strong research and development and production

team, short delivery time, quality assurance!

2.One-stop service (from product concept â model design/ makingâ

mold design/makingâmass production)

3.Various types: model development and production; injection mold design and

processing ;alloy die-casting mold design and processing; various toys toys product

production

4.From the concept provided by the customer to the development of the model

to the production of the mold to the mass production of the plastic product,

we provide a one-stop service with strong working teams and advanced equipment.

5.OEM customization service to meet various customization needs from customers

6. Perfect After-sales Service are provided, the first batch of product are available to

exchange for twice if needed!

Our business are as belowï¼

1ï¼Model development

⢠Product concept â Perform geometry understanding/functional requirement

analysis, communicate with customers â 3D modeling â Basic confirmation of

modeling, add mold/production factors to 3D â model creating and debugging

â Client confirmed the Model. Update 3D data âGet approval from client

â Polish and color the model if needed

⢠Model casesï¼

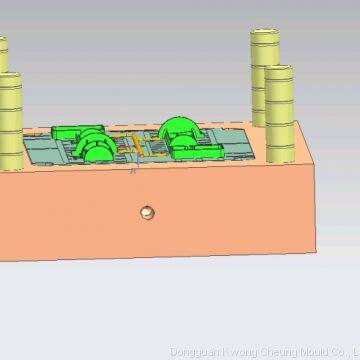

2ï¼Mold Making

1. Receive the tooling model or 3D from our clientï¼

2. Get to know product concept, conduct detailed analysis and evaluation

for both mold processing and plastic product, also communicate and align

with our clientï¼

3. Tooling 3Dï¼

4. Tooling design( MOLDFLOW will be applied on complex tooling)ï¼

5. Mold processing( Work-piece testing) ----Applied technology of CMM

and Semi- automation to shorten our mold-building lead time & cut down

the possibility of human errorsï¼

6. Mold assembly and debuggingï¼

7. Plastic sample assembly ( equipped with simple testing room and testing tools) ï¼

8. Actively solve mold problemsï¼

9. Proactively communicate product issues with customers and manufacturersï¼

10. Deliver & transfer the molds to the relative manufacturer on timeï¼

11. Cooperate with manufacturers to make sure their PS(Production Start) runs

smoothly.

3ï¼Mass Production for plastic products.

⢠Material mixxing â Injectionâ Remove injecting marks and flashes on the parts

â paint â dry â pad printing âsilk printingâ assemblyâInspection

â PackageâFinished products

Contact Us

IF YOU ARE INTERESTED IN INJECTION MOLD COST ,TOOL MAKER, PLASITC

INJECTION MOULDS OR YOU HAVE RELATIVE PROJECT TO OPEN THE

MOULDS ,PLEASE FEEL FREE TO SEND US INQUIRE THAT WITH SOME

HELPFUL INFORMATION SUCH AS SIZE ,MATERIAL,QUANTITY,

QUALITY REQUIREMENT,SCHEDULE,ETC.

WE WILL SEND YOU QUOATION BY EMAIL WITHIN TWO DAYS.

THANKS FOR YOUR ATTENTION!!!

Contact Us

- Dongguan Kwong Cheung Mould Co., Ltd

- Contact nameChristie Yeung Chat Now

- Phone86-769-82038228-318

- AddressQingxi, Dongguan, Guangdong

Product Categories

| Mould Design And Mould Processing | Injection Mold | Home Appliances | Toys |

| Medical Accessories | Automotive Parts | Daily Necessities |

New Products

-

Injection Mold Manufacturer Supplier Precision Mould Plastic Product Injection Mold

-

Medical Product Injection Mold Customization Service Blow Mould

-

Custom Plastic Injection Mold Maker Abs Plastic Mold Injection Molding Service

-

Medical Equipment Plastic Molding Manufacturing Plastic Injection Mold Maker

-

Customize Design And Manufacture Castle Toy Suit PU Prototype Model

-

Robot Toy Set Customize Mock Up Sample Design Prototype Model

-

OEM Carriage Toy 3D Printing Toy Prototype Model Customize

-

Oem Toy Prototype Model Cnc Machining Prototyping Model Design

-

Customize CNC Rapid Plastic Prototype Model Toy Prototype Making

-

3D Printing Sla Toy Car Prototype Model Processing And Custom

-

Helicopter Toy Prototype Model Design And Model Creating

-

SLA Printing Prototype Carriage Toy Prototype Model Customize Model Design

-

Customize Model Creating And Design Prototype Model Manufacturer

-

Customize Model Design And Model Creating Castle Toy Prototype Model

-

3D Design Prototype Model CNC Mechanical Engineering Robot Toy Rapid Prototyping

-

Toy Car Model Prototype CNC Machining Service Prototype Manufacturers

-

Toy Car Model Prototype CNC Machining Service Prototype Manufacturers Model design model making

-

Customize Service Plastic Injection Molding Injection Mold Manufacturer

-

Injection Mold Processing Plant Medical Plastic Parts Plastic Mold

-

Toy Injection Mould Injection Mold Processing And Design

-

Oem Customized Plastic Enclosure Mould Plastic Injection Mold

-

Factory Custom Design Plastic Parts Precision Plastic Injection Mold Maker

-

Precision Injection Mold Making Factory Plastic Products Mould

-

OEM Manufacturer Plastic Part Molding Injection Mold Custom

Popular Searches

- plastic extruder

- plastic injection

- plastic bottle

- cosmetic jar

- production line

- Plastic Injection Mould

- Making Machine

- glass bottle

- Injection Molding Machine

- Plastic Injection Molding Machine

- Moulding Machine

- Plastic Injection Molding

- plastic molding

- Blowing Molding Machine

- Injection Blow Molding Machine

- Injection Blow Moulding Machine

- Bottle Blow Molding Machine

- blow molding machinery

- Injection Stretch Blow Molding Machine

- Stretch Blow Moulding Machine

- Extrusion Blow Moulding Machine

- blow moulding

- injection machinery

- Injection Port

- pc light bulb

- plastic machine

- plastic mould

- plastic parts

- plastic injection

- plastic cover

Recommended Products

- Custom Plastic Molds

- Automotive plastic injection molds

- Negative Pressure Physiotherapy Tank Molds

- PLC Casing Molds

- Daily Necessities Molds

- Automobile Ignition Coil Plug Molds

- Car Signs Molds

- Concrete paving brick mold

- injection mold for plastic membrane chamber filter press plate

- 470*470mm to 2000*2000mm hydraulic injection machine mold for plastic membrane chamber filter press plate mold

- 2000*2000mm 4100 Tons Plastic injection mold for plastic membrane chamber filter press plate Hot Runner pp pe pvc

- 470*470mm to 2000*2000mm 500 tons to 4100 Tons Plastic injection mold for membrane chamber filter press plate Hot Runner

Find Similar Products By Category

- Mechanical Parts & Fabrication Services > Moulds

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Christie Yeung

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Christie Yeung

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile