Home > Products > kailitemachinery01 > Wood Plastic Extrusion Line

Wood Plastic Extrusion Line

- 10 Pair / Pairs per Month

- T/T

Product Description

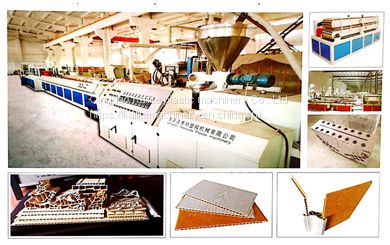

Our company develop this wood plastic extrusion line which is fully mixed with raw materials such as PVC, PP, PE and other plastics and plant fibres such as Wood flour, rice husk, straw, and then subjected to plastic processing techniques such as extrusion, moulding, and injection moulding to produce plates or profiles.

This production line is mainly used to produce WPC profile, such as Ceiling, Deck, Floor, Cornice, Plank, Windows, Door frame and board and etc.

Wood Plastic Extrusion Line List

PVC Wood-Plastics Composite Wallboard Production Line

PVC Wood-Plastics Composite Wallboard Production Line

WPC Extrusion Production Equipment

WPC Extrusion Production Equipment

Operating Regulations of Wood Plastic Extrusion Production Line

1. Inspection in front of the machine: In order to avoid human negligence causing unstable quality or stoppage in the middle, inspection work must be done and handover records must be made before starting the machine. If you want to check whether the circulating water circuit is unblocked; check whether the refrigeration system can work normally, etc.

2. Install the mold: correctly install the target mold, and adjust the extrusion mold and the shaping mold to the same.

3. Preheating: According to the characteristics of the extruder and wood-plastic raw materials, the barrel and die of the extruder must be heated before production.

4. Startup: After the above inspection and procedures are confirmed to be correct, prepare to start up.

5. Shutdown: When a working period is over or when it needs to be shut down for other reasons, prepare to shut down. Turn off the unloading motor, and put down the cleaning material at the unloading port.

6. Record: At the end of a shift, clean and maintain the machine.

Benefits of Wood-plastic extrusion production line

Wood-plastic extruder production line, the use of special design barrel screw and extruder production of wood products. Extruder stand-alone or two-stage mixing directly out, can also be granulated after the second extrusion, saving space, with high yield, extrusion pressure stability, preheating feeder placed at the top of the host, the first out of most Wood powder in the residual moisture, so that the host feeding section is more substantial, improve the plasticizing effect and so on. Screw design using a small shear force, not easy to cut wood fiber, can make the material in the barrel to stay within the time evenly. Barrel screw with inlaid alloy and spray wear-resistant corrosion-resistant alloy, greatly extending the service life.

The production line by a series of conical twin screw extruder, vacuum forming machine, traction machine, cutting machine, stacker. It can be used in a variety of plastic products.

Kailite is a plastic crusher company, we provide wood plastic machine, extrusion line and etc. Want to know more? Please contact us.

Contact Us

- Qingdao Kailite plastic machinery Co., Ltd

- Contact namePeter Tai Chat Now

| kailitemachinery | 20211026 | kailitemachinery01 |

-

HDPE Water And Gas Pipe Production Line

-

Kailite Plastic Extrusion Machinery

-

Automatic Drying And Feeding Machine

-

Automatic Plastic Mixer

-

Extrusion line Auxiliary Equipment

-

Melt Blown Fabric Production Line

-

No Chip Plastic Cutting Machine

-

PE Foamed Sheet/Film Production Line

-

SJSZ Conical Twin Screw Extruder

-

SWP Series Crusher

-

Wood Plastic Extrusion Line

-

WPC Extrusion Production Equipment

Popular Searches

Recommended Products

- Fridge Door Rubber Gasket Welder Refrigerator TPE Seal Automatic Soldering Welding Machine

- Cord Composite Packing belt making machine polyester yarn composite strap machine

- Compostie cord packing strap extruding prodcution line

- Compostie cord packing strap prodcution line polyester yarn reinforced strap making machine

- DOING 2024 waste plastic to diesel recycling plant waste plastic pyrolysis plant and waste oil distillation machine

- Automatic Rubber Cutting Machine, Cut the SBR/NBR/BR/FKM into small pieces

- Automatic Factory Foam Sponge Flat Disc Cutting Machine

- Refrigerator Door Gasket Automatic Magnetic Strip Cutting and Inserting Machine

- Magnetic Strip Cutting and Inserting Making Machine for Refrigerator Fridge Door Gasket

- Plastic Door Gasket Magnetic Strip Cutting and Inserting Machine

- Magnetic Strip Cutting and Inserting Machine for Freezer Gasket/Magnetic Strip Inserting Machine

- Machinery >> Plastic & Rubber Machinery >> Other Plastic & Rubber Machinery

Find Similar Products By Category

- Machinery > Plastic & Rubber Machinery > Other Plastic & Rubber Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Peter Tai

Welcome to my shop! Glad to serve you!Please send your question!

Peter Tai

Welcome to my shop! Glad to serve you!Please send your question!

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 20 to 5000 characters.Send Now.

-

*Email

Please input the mailbox.

-

Mobile