Home > Products > Feeding&Conveying Series > Xiecheng Efficient Production Process Auto Central Material Feeding System

Xiecheng Efficient Production Process Auto Central Material Feeding System

Negotiable

1 (Min.Order)

- 1000 per Month

- T/T Credit Card

You May Like

-

Central Material Feeding System Mini Auto Centralized Feeding System

-

CE Industrial Hot Air Plastic Granules Dryer Hopper Dryer Plastic Drying Machine

-

High Efficiency Energy Saving Plastic Granules Pellet Heater Hopper Dryer Machine

-

Economical Potent Euro Hopper Dryer For Injection Machine

-

Euro Plastic Material Standard Hopper Dryer

-

PET Honeycomb Rotor Dehumidifying Dryer Machine Industrial Plastic Honeycomb Dehumidifier

Product Description

Product Description

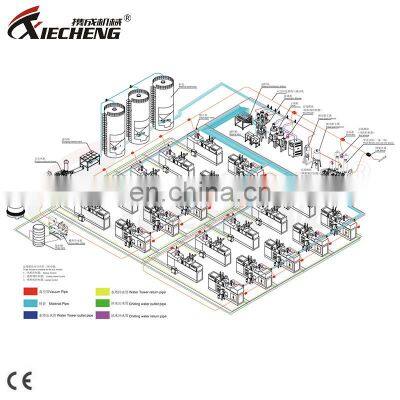

CENTRALIZED FEEDING SYSTEM

The Centralized Feeding System is an overall solution for customer’s whole plant to realize central conveying, central controlling and continuous unmanned forming production, by design according to the equipment locale conditions in customer’s facilities and raw materials consumptions with proper requirement for auxiliary equipment.

New Factory Planning

Old Factory Renovation & Upgrading

System Components

The components of the central feeding system mainly include: central operating station, roots blower, central filter (cyclone dust collector), central filter (pulsating dust collector), central coupling station, storage barrel, platic mixer,hopper dryer, honeycomb dehumidifier, gravimetric blender, central hopper loader, plastic crusher, online plastic granulator,manipulator, cut-off valve, cut-off valve, suction pipe and air pipe, etc.

Feature

▪ Efficient production process;

▪ Tidy production site;

▪ Flexible on-site management;

▪ Production cost is greatly reduced;

▪ Product quality is significantly improved;

▪ Completely enhances the company image.

If you want more sizes, please contact us for details

Product Details

Storage

For material storage, Xiecheng’s offer for both granules and flakes ranges from outside and inside silos. As a completion, dedicated filtering devices for the conveying air and dust separation systems are also available.

Drying Technologies

In plastic molding process, drying becomes the most critical step which must be seriously taken and the moisture in the material must be removed at a reasonable temperature. Xiecheng dehumidifying dryer can provide dew-point of -40℃ or even lower. Also it can achieve constant detection of all the parameters and stabilize the dew-point.

Conveying System

The distribution to the final destinations can be carried out through a flexible variety of piping, choosing among the most appropriate solution for any kind of material. Like one-material-one-pipe conveying method, or automatic distribution station to classify the raw materials.

Injection Molding

Industrial computer is adopted to automatically control over all of the material consumption units in this system, hence realizing 24 hours continuous feeding and production. With particular functions of each device in the system, it can perfectly realize the specific requirement for raw materials by dehumidifying, drying, conveying, dosing, mixing, etc. Equipped with multiple monitoring and protection functions, the centralized feeding system is safe and reliable and is the core precondition to realize unmanned industrial manufactory.

Application Range

About Us

Company Profile

In 2009, founded by Mr. Fuzhibo with its head quarter in Jiangmen city which known as a famous hometown of many overseas Chinese, Jiangmen Xiecheng Machinery Co., Ltd. has been devoted herself to be an integrated enterprise of R&D, manufacturing and marketing businesses for High-end Industrial Refrigeration Equipment, Rubber and Plastic Moulding Auxiliary Automation Equipment, and also Intelligent Integrated System Solutions.

Authenticated by IS09001, XIECHENG also successfully established the “6+1+C” full dimensional product service system with her own supply chain advantages of combining the six series of products, as Industrial Refrigeration, Mould Temp. Controlling, Material Conveying, Crushing & Recycling, Dehumidifying & Drying, and also Mixing, into central intelligent system solutions as Material Feeding, Air Supply, Water Supply and Power Supply, to fast fitting customers’ specific demands.

VR

Company Certificate

Exhibition

Contact Us

- Jiangmen Xiecheng Machinery Co.,Ltd.

Product Categories

New Products

-

CE Standard PU Plastic Material 3 in 1 Dryer Honeycomb Dehumidifier Dryer

-

Stainless Steel Dehumidifying Drying Honeycomb Dehumidifier Unit Plastic Hopper Dryer Machine

-

High Efficiency Plastic Hot-Air Oven Dryer Cabinet Dryer

-

300kg Small Extruder Plastic Hopper Dryer For Injection Machine

-

Plastic Gravimetric Doser Blender Weigh Scale Gravimetric Batch Blender

-

Plastic Resin Automatic Mixer Machine Gravimetric Dosing Blender

-

Automatic Plastic Color Masterbatch Mixing Machine Small Screw Volumetric Doser

-

16mm Double Screw Color Volumetric Doser

-

Full Stainless Steel CE Vertical Blender Plastic Material Granules Mixer Machine Plastic Mixer

-

Xiecheng Plastic Granules Euro-Mixing Storage Tank Material Plastic Color Mixer

-

CE Industrial Blending Vertical Plastic Color Mixer

-

Xiecheng Plastic Color Mixer Volumetric Ratio Plastic Mixer of Two Feed Mixer

-

High Quality Low Noise Water Cooling Tower

-

Water System Small Closed Cooling Tower for Industrial

-

Xiecheng Recycling Waste Plastic Crusher Plastic Scrap Crusher Machine

-

Wholesale Price CE R22 5HP Industrial Air Cooled Water Chiller For Sale

-

300KG Plastic Material Autoloader Mini Vacuum Loader For Sale

-

Xiecheng 50KG 2HP Plastic Resin Raw Material Color Mixer Machine

-

Xiecheng Strong Stuction Force 300Kg/h Plastic Material Auto Hopper Loader For New materials

-

Xiecheng Water Type Intelligent Injection Mold Temperature Controllers

-

Xiecheng CE Standard 50KG Hot Air Plastic Granules Dryer Machine Hopper Dryer

-

New Condition Plastic Industrial Water Screw Chiller for Sale

-

Mini plastic film shredder plastic crushing machine for injection moulding

-

Plastic crusher air auto loader hopper loader automatic loader

Popular Searches

Recommended Products

- Multi-station Vacuum Plastic auto Loader Suction Machine Price

- vacuum hopper loader plastic pellet auto loader price

- plastic vacuum autoloader for plastic pellet feeding machine

- Euro Plastic Vacuum Loader Suction Machine Feeding Machine Feeder Autoloder

- Euro Automatic plastic vacuum loader for granule pellet

- High Quality Separate Type Hopper Loader Plastic pellets Vacuum Hopper Loader Industrial material auto loader

- Wholesale Euro-type vacuum hopper loader automatic feeding machine for plastic pellets

- China Manufacture Industrial Vacuum Suction Loading Machines Factory Price Automatic Plastic Raw Material Hopper Loaders

- Industrial vacuum loader factory Sale Various plastic raw material hopper loader

- Wholesale vacuum plastic pellets extruder hopper loader auto screw hopper loader

- Wholesale plastic hopper auto loader for injection molding machine

- Wholesale plastic material hopper loader Plastic Pellets Material Vacuum Hopper Auto Loader For Injection Molding Machine

Find Similar Products By Category

- Machinery > Plastic & Rubber Machinery > Plastic Raw Material Machinery > Plastic Loader

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now

Jiangmen Xiecheng Machinery Co.,Ltd.

AIBot OnlineThis conversation is AI-generated. Contact manufacturer before transaction to confirm info.

-

sales

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

sales

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile