Home > Products > Profile & Roughness measuring machines > Nano Level 3D Surface Profilometer Measuring Machine Measurement Profile And Roughness Tester In China Contour Instrument

Nano Level 3D Surface Profilometer Measuring Machine Measurement Profile And Roughness Tester In China Contour Instrument

Negotiable

1 (Min.Order)

- 1000 per Month

- T/T Credit Card

You May Like

-

Non-Touch 3D Measuring Machine Measurement Instrument Profile And Roughness Tester Contour Surface Profilometer In China

-

Non-Touch Nano Technology Measuring Instruments Surface Profilometer In China

-

Nanometer Nano Technology Laser Scan Profilometer 3D Machine Surface Measuring Instrument

-

Level Nano Technology Measuring Instruments Laser Scan Surface Profilometer 3D Machine Profile And Roughness Tester

-

Nanometer Nano Technology Measuring Surface Profilometer In China

-

Optical 3D Profilometer Measuring Machine Instrument Profile And Roughness Tester Contour In China Surface Measurement

Product Description

Product Overview

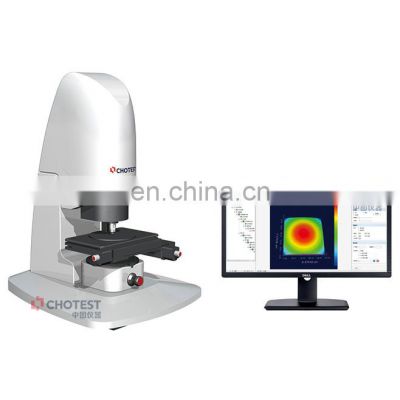

W1 Nano 3D Optical Surface Profilometer

SuperView W1 Optical 3D Surface profilometer is an ideal instrument for sub-Nanometer measurement of various precision parts. Based on the principle of white light interference technology, combined with precision Z-direction scanning module and 3D modeling algorithm, it contactlessly scans the surface of the object then establish a 3D image for the surface. A serial of 2D, 3D parameters reflecting surface quality of the object are obtained after XtremeVision software processes and analyzes the 3D image.

The SuperView W1 is a user-friendly precision optical instrument with powerful analysis functions for all kinds of surface form & roughness parameters. With unique light source it could measure various precision parts with both smooth and rough surface.

The SuperView W1 is a user-friendly precision optical instrument with powerful analysis functions for all kinds of surface form & roughness parameters. With unique light source it could measure various precision parts with both smooth and rough surface.

FEATURES AT A GLANCE

PRODUCT SPECIFICATIONS

|

Light Source

|

White/Green LED

|

||||

|

Image System

|

1024*1024(Optional 2048×2048)

|

||||

|

Objectives

|

10×,50× ,(Optional 2.5×,5×,20×,100×)

|

||||

|

Optical zoom

|

1×(Optional 0.5×,0.75×)

|

||||

|

Lens holder

|

3 holes(Optional 5 holes)

|

||||

|

XY Stage

|

Size

|

320*200mm

|

|||

|

Moving range

|

140*100mm

|

||||

|

Loading capacity

|

10kg

|

||||

|

Control Type

|

Motorized

|

||||

|

Resolution

|

0.1μm

|

||||

|

Tilt

|

±5°(Manual)

|

||||

|

Z Stage

|

Moving range

|

100mm( Motorized)

|

|||

|

Scanning range

|

10mm

|

||||

|

Scanning speed

|

45μm/s

|

||||

|

Resolution

|

0.1nm

|

||||

|

Reflectivity of testing object

|

0.05%~100%

|

||||

|

Step Height measurement

|

Accuracy

|

0.7%

|

|||

|

Repeatability

|

0.1% 1σ

|

||||

Note:

Performance parameters are tested by using a 4.7µm precision master stage gauge in lab according to ISO 4287 and ISO

25178.

Performance parameters are tested by using a 4.7µm precision master stage gauge in lab according to ISO 4287 and ISO

25178.

|

Zoom ratio of lens

|

2.5×

|

5×

|

10×

|

20×

|

50×

|

100×

|

||||

|

Numerical hole diameter

|

0.075

|

0.13

|

0.3

|

0.4

|

0.55

|

0.7

|

||||

|

Optical resolution @550nm(µm)

|

3.7

|

2.1

|

0.92

|

0.69

|

0.5

|

0.4

|

||||

|

Depth of focus(µm)

|

48.6

|

16.2

|

3.04

|

1.71

|

0.9

|

0.56

|

||||

|

Working distance(mm)

|

10.3

|

9.3

|

7.4

|

4.7

|

3.4

|

2

|

||||

|

Field H×V (mm)

|

Video system

1024×1024 |

0.5×

|

3.84×3.84

|

1.92×1.92

|

0.96×0.96

|

0.48×0.48

|

0.192×0.192

|

0.096×0.096

|

||

|

0.75×

|

2.56×2.56

|

1.28×1.28

|

0.64×0.64

|

0.32×0.32

|

0.128×0.128

|

0.064×0.064

|

||||

|

1×

|

1.92×1.92

|

0.96×0.96

|

0.48×0.48

|

0.24×0.24

|

0.096×0.096

|

0.048×0.048

|

||||

|

Video system

2048×2048 |

0.5×

|

8.96×8.96

|

4.48×4.48

|

2.24×2.24

|

1.12×1.12

|

0.448×0.448

|

0.224×0.224

|

|||

|

0.75×

|

6.44×6.44

|

3.22×3.22

|

1.61×1.61

|

0.805×0.805

|

0.322×0.322

|

0.161×0.161

|

||||

|

1×

|

4.48×4.48

|

2.24×2.24

|

1.12×1.12

|

0.56×0.56

|

0.224×0.224

|

0.112×0.112

|

||||

Built-in ISO/ASME/EUR/GBT Standards of 2D, 3D parameters:

2D Parameters

3D Parameters

Products Application

It is used for measurement and analysis of surface roughness and profile of precision components from industries of

semi-conductor, 3C Electronics, ultraprecise machining, optical machining, micro-nano materials, micro-electro-mechanical system.

semi-conductor, 3C Electronics, ultraprecise machining, optical machining, micro-nano materials, micro-electro-mechanical system.

More Application

Measurement and analysis for various products, components and materials`surface form and profile characteristics, such as flatness, roughness, waviness, appearance, surface defect, abrasion,corrosion, gap, hole, stage, curvature, deformation, etc.

3C Electronics_Sapphire crystal

3C Electronics _ Ink screen

Product packaging

Standard

1. Host machine * 12. Video System *1

3. Optical Zoom 0.5x * 1

4. Objective Lens 10x * 1

5. XY stage *1

6. Lens holder 3 holes-type *1

7. Computer

8. 4.7μm calibration step

9. Operating handle

10. XtremeVision Software

11. Automatic multi-area measurement, automatic splicing measurement module

12. electrical control cabinet

13. TGY30-680-30L air compressor

14. Aluminium alloy suitcase for accessories

15. User manual

16. Product certification and Warranty card

Optional

1. Optical Zoom 0.75x, 1x

16. Product certification and Warranty card

Optional

1. Optical Zoom 0.75x, 1x

2. Objective Lens 2.5x, 5x, 20x, 50x, 100x

3. Vacuum table 4'', 6'', 8'' etc

4. 5-holes lens holder

Why Choose Us

CHOTEST is not only a software company but also a national high-tech enterprise integrating research, development, production and sales, which is specialized in designing and producing precision measurement instruments, calibration instruments and 3D Optical surface profilometer for Nano 3D contour and roughness measurement.

The company has 2,000 square meters of modern office well equipped with advanced research facilities. In addition, it owns 5,000 square meters of precision machining and assembly factory. All products are manufactured in accordance with ISO9001 standard. The company is always living up to the motto that is providing our customers with top quality products.

At present, the company has dozens of self-developed products with new technology, widely used in government Metrology and Quality Inspection agencies, international military, automotive, aerospace, machinery, metallurgy, electric power, petrochemical and other industries. The company also has involved in developing a number of national standards and has made its due contribution for China's metrology and testing technology progress.

CHOTEST focuses on technology development of precision measurement equipments and sophisticated testing equipments. It constantly challenges to all kinds of technical barriers and technology monopoly. The goal of the company is to provide high-end measuring equipments to manufacturing industry in all over the world.

The company has 2,000 square meters of modern office well equipped with advanced research facilities. In addition, it owns 5,000 square meters of precision machining and assembly factory. All products are manufactured in accordance with ISO9001 standard. The company is always living up to the motto that is providing our customers with top quality products.

At present, the company has dozens of self-developed products with new technology, widely used in government Metrology and Quality Inspection agencies, international military, automotive, aerospace, machinery, metallurgy, electric power, petrochemical and other industries. The company also has involved in developing a number of national standards and has made its due contribution for China's metrology and testing technology progress.

CHOTEST focuses on technology development of precision measurement equipments and sophisticated testing equipments. It constantly challenges to all kinds of technical barriers and technology monopoly. The goal of the company is to provide high-end measuring equipments to manufacturing industry in all over the world.

FAQ

1. Are you factory?

Yes, we are specialized in designing and producing precision measurement instruments and calibration instruments.

2. How many years experience do you have?

We have 16 years experience on measurement instruments and calibration instruments since 2002.

3. What size of your factory?

We have 5000 square meters of factory and 2,000 square meters of modern office

4. Can you accept OEM and ODM?

No, we only sell the products under Chotest brand.

5. Can I become your distributor of 3D Optical surface profilometer??

Yes, please contact our sales engineer.

6. What is the lead time?

Lead time is 30-60days in usual.

7. What is your payment term?

30% deposit first, balance payment before delivery.

We accept T/T, L/C.

8. How to install the machine?

We dispatch our engineers to install and debug the machine in site of the customer.

9. What is your warranty term?

We provide 1 year warranty after acceptance inspection by customer.

Free repair or replacement in 1 year warranty in case of any problem.

Response in 12 hours for emails or calls from customers in working days.

Yes, we are specialized in designing and producing precision measurement instruments and calibration instruments.

2. How many years experience do you have?

We have 16 years experience on measurement instruments and calibration instruments since 2002.

3. What size of your factory?

We have 5000 square meters of factory and 2,000 square meters of modern office

4. Can you accept OEM and ODM?

No, we only sell the products under Chotest brand.

5. Can I become your distributor of 3D Optical surface profilometer??

Yes, please contact our sales engineer.

6. What is the lead time?

Lead time is 30-60days in usual.

7. What is your payment term?

30% deposit first, balance payment before delivery.

We accept T/T, L/C.

8. How to install the machine?

We dispatch our engineers to install and debug the machine in site of the customer.

9. What is your warranty term?

We provide 1 year warranty after acceptance inspection by customer.

Free repair or replacement in 1 year warranty in case of any problem.

Response in 12 hours for emails or calls from customers in working days.

Contact Us

- Chotest Technology Inc.

Product Categories

New Products

-

High precision Nanometer Level 3D Surface Measurement Instrument Made In China

-

High accuracy Cnc Parts Profilometer And Roughness Contour Measuring Machine

-

Metrology Institute Use Thread Measuring Profilometer Stylus Made In China for roughness measurement

-

High Accuracy Made In China Laser Interferometer For Precision Length Measuring

-

CNC supported High Accuracy Single Frequency Interference Linear Guide Testing Laser

-

For Machine Tool Testing use High Accuracy Measuring Motion Platform Detection Length Coordinate Laser Interferometer

-

Factory CNC calibration High Accuracy Parallelism Measuring Motion Laser Interferometer For Precision Measurement

-

Coordinate Measuring High Precision Laser Interferometer CNC support

-

Calibration Laboratory Cnc Supported Machine Tool Detection Length Laser Interferometer Instrument for big work pieces

-

Ultra Single Frequency High Precision Laser Interferometer for factory CNC calibration

-

Wide range High Accuracy Cnc Tools Laser Interferometer For Coordinate Measuring Machine

-

High Accuracy Single Frequency Interference Linear Guide Cnc Guideway Laser Interferometer

-

High Precision Interferometer Machine Tool Detection Single Frequency Laser Interference

-

Cnc Supported Measuring Motion Ultra Precision Laser Interferometer

-

High Interferometer Made In China Instrument Precision Single Frequency Laser Interference

-

Cnc Supported Single Frequency High Precision Laser Interferometer

-

Accuracy Ultra Single Frequency Interference Linear Guide Testing Made In High Precision Laser Interferometer

-

High Accuracy Coordinate Machine Cnc Tools Laser Interferometer For Measuring Motion Platform

-

High Accuracy Measuring Motion Platform Laser Interferometer For Parallelism Measurement

-

Cnc Supported Precision Laser Interferometer For Machine Tool Detection

-

High Ultra Precision Interferometer Single Frequency Interference Made In China Linear Guide Testing Laser

-

Cnc Supported Made In China Instrument High Precision Laser Interferometer

-

Accuracy Single Frequency High Precision Laser Interferometer

-

High Precision Cnc Tools Calibration Cmm Accuracy Testing Laser Interferometer For Coordinate Measuring Machine

Popular Searches

Recommended Products

- railway Joint Gap Measuring Device for Railway Track Joint Clearance Measurement

- Stainless Rail Taper Welding Gap Inspection Gauge

- Digital rail cant device used for measuring Track superelevation gauge railway maintenance equipment

- Rail Cant Measurement Device For Rail Inclination Measuring Device

- Rail carrying tong 2 ton/3 ton rail lifter carrying tong equipment

- 3 Ton Rail Lifting Carrying Tongs

- A-Frame Rail Aligner for Aluminothermic Track Welding

- Rail Alignment Frame / A Frame / Alignment "A" Frame for Rail Welding Process

- Rail rerailer device for railway maintenance

- Rail track rerailing device track rerailer for railway maintenance

- Railway rolling digital track gauge for measuring rail distance digital rail ruler

- Track Gauge Railway Measuring Tools for Track Maintenance

Find Similar Products By Category

- Measurement & Analysis Instruments > Measuring & Gauging Tools > Other Measuring & Gauging Tools

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now

Chotest Technology Inc.

AIBot OnlineThis conversation is AI-generated. Contact manufacturer before transaction to confirm info.

-

sales

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

sales

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 20 to 5000 characters.Send Now.

-

*Email

Please input the mailbox.

-

Mobile