Home > Products > Tube Machine > HF Welded ERW Automatic Tube Forming Mill Line

HF Welded ERW Automatic Tube Forming Mill Line

- 150 Set / Sets per Month

- Shanghai port

- T/T L/C

- 3 days

You May Like

-

Low Carbon Steel Seam Welded Cold Formed Tube Mill Line

-

High Precision Structure Steel Round/Square Tube Production Line

-

Steel Tube Welding Machine Pipe Mill Production Line

-

Carbon Steel Longitudinal Seam Welding Pipe Profile Making Equipment Factory

-

Tube Line Factory ERW Steel Tube Welding Machine

-

ERW Metal Hollow Steel Box Section Making Machine

Product Details

| Brand Name | TG | Place of Origin | China | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Step1: Uncoiler

Uncoiler the function is to support and expand the strip, so strip can enter into machine to roll forming. Strip can be expanded by hydraulic or pneumatic and uncoiler can be rotated 180 degree. Strip expand speed can be adjusted, braking device designed with pneumatic or hydraulic cylinder to press the brake rubber block

Step2: Shear & end welding

It is used to shear the head and the end of the steel strip of two steel coils, cutting off the irregular part then welding two steel strips, so machine can work continuously.

Step3: Accumulator

Installed between shear & end welder and forming mill, horizontal spiral accumulator store a large amount of strip in a reasonable footprint space to give enough time for shear & end welder to cut and join the ends of two successive coils with non-stop tube mill

It has vertical cage type accumulator for small size tube mill

Step4: Forming

The function of this part is to make the steel strip become to the tube blank by forming rollers

Step5: welding & scarfing

The function of this part is to center the welding seam and guide the tube blank to welding device, so the welding seam will be closed before welding, use scarfing tool to remove the burr to ensure the smooth welding

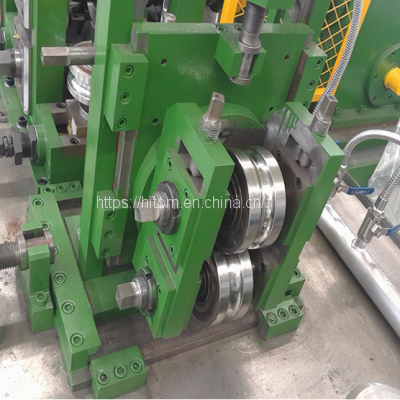

Step6: Sizing

The function of this part is used to finish the tube blank from the forming machine, so the tube size can meet the physical dimension as customer required, form to square and rectangular and other shape profiles

Step7: Straightening

4 rolls turk head straightening, straighten pipe online to achieve the ideal flatness

Step8: Cut off saw

Cut off the pipe with required length, length of pipe can be set

With option of cold saw and flying saw

Step9: Run out table

This unit is to convey the finished pipe to packing, pipe transmit by dynamic roll. A signal sensing device installed in the end of run out table, when pipe touch the signal sensing device, it will feedback the signal to control panel, control panel start working and discharge the pipe

Contact Us

- Taicang Global Machinery Co., Ltd

- Contact nameTom Yang Chat Now

- Phone86-512-53705537

- AddressTaicang, Suzhou, Jiangsu

Product Categories

| Tube Machine | Slitting Machine | Cut to length machine | Roll Forming Machine |

| Cold rolling mill | Pickling Line | Spare Parts & Consumables | Auxiliary Equipment |

New Products

-

Mild Steel Round/Square Pipe Rolling Mill Equipment

-

Carbon Steel Round Square Rectangular Pipe Profile Mill Production Line

-

Strong Robust Longitudinal Seam Cold Formed Profile Cross Section Making Machine

-

High Speed Electric-Welded Steel Pipe Production Machine

-

GI Automatic Steel Tube Profile Production Line

-

Low Carbon Steel Welded Profile Making Equipment Tube Manufacturing Machine

-

Seam Welded Steel Pipe Making Machine Line

-

TG45 Steel Round/Square Tube Production Line

-

Galvanized Steel Round/Square Pipe Tube Making Machine Production Line

-

High Speed Hollow Steel Section Manufacturing Line

-

High Frequency Carbon Steel Seam Welding Tube Line

-

Welded Circular Steel Hollow Section Pipe Tube Making Machine

-

High Frequency Straight Seam Mild Steel Pipe Milling Line

-

Direct Form Square Pipe Mill

-

Pipe Mill HF Carbon Steel Pipe and Profile Making Machine

-

HF Welded Carbon Steel Pipe Tube Mill Production Line

-

Pipe Welding Machine China GI Steel HF Precision Pipe Production Line

-

Galvanized Steel High Frequency Seam Welded Pipe Rolling Machine

-

Heavy Gauge Round/Square Pipe Profile Mill Plant

-

High Frequency Quick Change ERW Low Carbon Steel Pipe Manufacturing Machine

-

High Speed Round/Square High Frequency Seam Welded Pipe Line Tube Line

-

Black Steel Pipe Making Machine For Full Hard Cold Rolled Coil Strip

-

HF Galvanized Steel Pipe Forming Mill Machine Line

-

High Frequency Straight Seam Low Carbon Steel Pipe Forming Line

Popular Searches

- plastic extruder

- production line

- extrusion line

- ball mill

- pipe welding machine

- pipe making machine

- pipe production line

- pipe machine

- roller mill

- Hand Crimping Tool

- Hydraulic Crimping Tool

- tube making machine

- tube production line

- pipe mill

- rubber mixing mill

- open mixing mill

- Erw Pipe Mill

- Steel Pipe Mill

- Roll Forming Mill

- Pipe Welding Mill

- Tube Mill Line

- Pipe Making Mill

- Tube Welding Mill

- Tube Making Mill

- pipe welding machine

- pipe making machine

- pipe production line

- pipe machine

- flour mill

- Rice Mill

Recommended Products

- Exhaust Pipe EGR Tube Flaring Expander End Forming Machine, Auto Metal Tube End-Forming Steel Pipe Reducing/Shrinking Machine

- Automatic Stainless Steel Copper Aluminum Pipe End Reducing Machine Pipe End Shrinking Machine Tube End Forming Machine

- Manufacture Sells PLC Control 4 Stationes Pipe End Forming Machine

- Automatic Reducing Expanding Flanging Pipe End Forming Machine

- Round Tube Square Tube Reducing Forming Machine Automatic Pipe End-Forming Machine

- Hydraulic Stainless Steel Pipe End Expanding Machine for Pipe Expander or Tube Reducer

- Multi Station Automatic Square Tapper Pipe Tube End Reducing Forming Machine Price

- Four Stations Pipe Forming Machine with Round Tube

- Tube Taper End Forming Machine Automatic Metal Tube Reducer Pipe End Shrinking Machine

- Pipe Tube End Forming Machine for Expanding Reducing Flaring

- Automatic Hydraulic Pipe End Forming Machine for Copper Pipe End Reducing

- Pipe End Forming Machine Reducing Machine for Reducing Expanding Flanging

Find Similar Products By Category

- Machinery > Metal & Metallurgy Machinery > Other Metal & Metallurgy Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Tom Yang

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Tom Yang

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile