- Hebei YUBO Filtration Equipment Co., Ltd.

- Main products:wedge wire screen ,stainless steel filter element ,filter housing ,sentered filter ,self-cleaning filter ,Johnson filter ,wedge wire screen panel ,wedge wire screen pipe ,Stainless steel sieve bend screen ,wedge wire screen nozzle ,Wedge Wire Distributors Screen ,Wedge Wire Cylindrical Strainer

Home > Products > stainless steel filter housing > Self-Cleaning Irrigation Water Filters

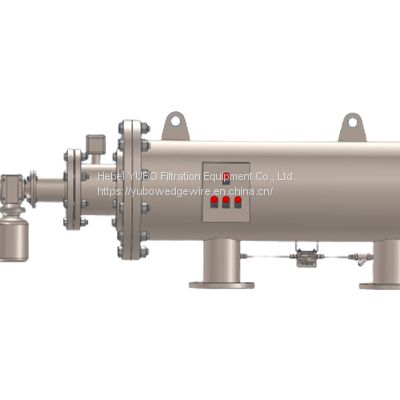

Self-Cleaning Irrigation Water Filters

- 50 Set / Sets per Month

- tianjin,shanghai,ningbo,qingdao,guangzhou

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- 30 days

Product Details

| Place of Origin: | China |

Product Description

One of the critical components of successful agriculture is irrigation, which ensures that crops receive the water they need to thrive. However, using untreated or impure water for irrigation can have detrimental effects on crops and the environment. Self-cleaning irrigation water filters have emerged as a groundbreaking solution to this problem.

The Importance of Self-Cleaning Irrigation Water Filters

Clean irrigation water is essential for the health and productivity of crops. Using water contaminated with sediment, debris, or microorganisms can lead to clogged irrigation systems, reduced water flow, and the spread of diseases among plants. Additionally, the accumulation of contaminants in the soil can degrade its quality over time, affecting future crop yields. To tackle these issues, self-cleaning irrigation water filters have become an indispensable tool for modern farmers.

We design and produce self-cleaning filters according to agricultural irrigation requirements, contact us now!

E-mail: sales@uboscreen.com

WhatsApp: 86 13653285589

The Technology and Key Components of Self-Cleaning Irrigation Water Filters

Self-cleaning irrigation water filters are engineered to automatically remove impurities and contaminants from the water before it reaches the irrigation system. This technology relies on a few key components:

1. Filter Screen: The central component of the system is the filter screen, typically crafted from stainless steel or robust plastic. Water flows through this screen, effectively trapping sizable particles such as sand, silt, algae, and leaves.

2. Backwash System: To keep the filter screen clear and functional, self-cleaning filters employ a backwash system. This system reverses the flow of water temporarily to dislodge and flush out trapped contaminants. The dirty water is typically expelled to a separate outlet, ensuring that only clean water continues to the irrigation system.

3. Control Mechanism: The self-cleaning process is automated and controlled by a system that monitors the pressure and flow rate within the filter. When the filter screen becomes clogged and the flow is reduced, the control mechanism triggers the backwash cycle.

Contact Us

- Hebei YUBO Filtration Equipment Co., Ltd.

- Contact nameDong Chat Now

- Phone86-311-85955658

- Addressyuhuaqu Shijiazhuang,Hebei

Product Categories

| Cone Filter&Strainer | Basket Filters | Wedge Wire Pipe | Sieve Bend Screen |

| wedge wire screen panel | SS filter nozzle | filter element | ss resin trap |

| Header Lateral | stainless steel filter housing |

-

False Bottoms Screens for Grain Brewing

-

water treatment sand filter nozzles

-

Stainless Steel Sieve Bend Screen

-

Wedge Wire Screen Cylinders

-

Parabolic Screen Filter

-

SS Johnson Type Wastewater Hydraylic screen

-

radical reactors wedge wire screen

-

SS Wedge Wire Cylindrical Strainer Filter

-

wedge wire screen panel for chemical plant

-

Stainless Steel Cone Filter Punching Screen

-

slurry thickener custom design

-

Stainless Steel Sintered Wire Mesh Perforated Metal Tubes

Popular Searches

Recommended Products

- OEM Sintered Porous Metal Powder Stainless Steel 316L air Stone Sparger

- OEM Sintered Porous Metal Stainless Steel 316L Sparger for Beer Brewing

- OEM Sintered Porous Metal Stainless Steel 316L Sparger

- OEM Sintered Porous Metal Stainless Steel 316L Aeration Stone Sparger

- OEM Sintered Porous Metal Stainless Steel 316L Diffusion Stone Sparger

- OEM Sintered Porous Metal Stainless Steel 316L air Stone Sparger

- OEM Sintered Porous Metal Stainless Steel 316L Carbonation Stone Sparger

- OEM Sintered Porous Metal Stainless Steel 316L Bubble Diffuser Sparger

- RT-144 Polyester melt filter Stainless steel CPF filter core

- RT-143 Extreme temperature Stainless steel filter component

- RT-142 petrochemical processing polymer manufacturing and power plants filtration metal filter eleme

- RT-140 industrial and synthetic fiber processing filtration system washable replacement cartridges

Find Similar Products By Category

- Machinery > General Industrial Equipment > Industrial Filtration Equipment > Other Industrial Filtration Equipment

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Dong

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Dong

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 20 to 5000 characters.Send Now.

-

*Email

Please input the mailbox.

-

Mobile