Home > Products > SG Ceramic Alumina > Ceramic Aluminum oxide Abrasive grain F150-F220 from China

Ceramic Aluminum oxide Abrasive grain F150-F220 from China

- 20000 Kilogram / Kilograms per Month

- Tianjin

- T/T L/C PayPal

- 7 days

You May Like

Product Details

| Brand Name | HAIXU Abrasives | Place of Origin | China | |

| Model Number | BCA | Material | Alumina | |

| Usage | bonded abrasives and coated abrasives | Abrasive Grain Sizes | F16-F220 |

Product Description

Ceramic Alumina grain

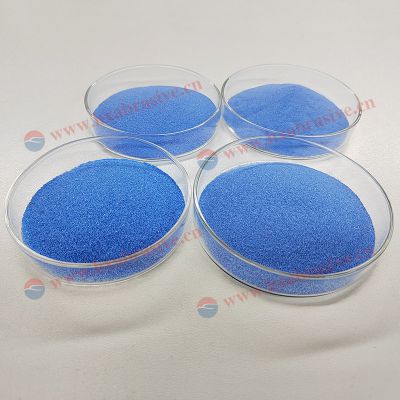

Ceramic Aluminum oxide Abrasive grain F150-F220 from China

Introduction of Ceramic Aluminum oxide Abrasive grain F150-F220 from China

Sol-Gel Alumina abrasive is a new type abrasive grain totally different from traditional fused alumina. Sol-Gel is also called ceramic alumina grain,it is made by sol-gel process.

α-Al2O3 micro-crystal always added as seed into the raw mixed materials of Al2O3 H2O micropowder and water. By doing so,crystal will get more compact when calcined to get solid sol-gel grains. The calcining and sintering process are very important to make sol-gel crystal get small α-Al2O3 crystal size.

The features of Ceramic Aluminum oxide Abrasive grain F150-F220 from China:

1. Small crystal size about 100-150nm, which is even much smaller than zirconia alumina. And it’s hundredths of the size of normal fused alumina grains.So it will make abrasive wheels increase lifetime by several times than ordinary wheels.

2. Excellent self-sharpening performance. The sol-gel grain will get new grinding edges after grinding. The edges are get from the single grain crystal instead of off a whole crystal. That makes the grain much sharper than normal fused alumina.

3. The microscopic hardness of sol-gel alumina is about 1900-2400 kgs/cm2,which is higher than zirconia alumina. Thus,sol-gel alumina can make grinding and cutting easier for special hard metal such as Nickel chromium alloy and nickel titanium alloy.

4. The roughness is double of normal fused alumina,and even higher than zirconia alumina.

5. Low temperature grinding is another significant property of Sol-gel alumina abrasive grain. That will avoid much heat during grinding and cutting, so it won’t get hurt of workpiece surface.

6. Small size grinding edges and sharp grinding can avoid tiny crackle on workpiece.

Physical propertiesof Ceramic Aluminum oxide Abrasive grain F150-F220 from China:

Product Name | SG Blue Ceramic Alumina Abrasive |

Method | Sol-Gel |

True Density | ≥3.90 g/cm³ |

Hv Hardness | 2100-2200(khf/mm³) |

Color | Blue |

Crystal size | 50-150nm |

Roughness | 65% |

Chemical composition ofSol-gel alumina abrasive grain

AL2O3 | 94-96% |

Y2O3 | 1-2% |

La2O3+NdO2 | 2-3% |

Applications of Sol-gel alumina abrasive grain:

Sol-gel alumina abrasive grain always mixed with other abrasive grains to make abrasive tools.

1. Diamondcuttingwheel.

2. Diamondvitrified gear grinding wheel.

3. High level resin boned grinding wheel.

4. High level vitrified bonded grinding wheel.

5. Centerless grinding wheel.

6. High level cutting disc.

7. High level coated abrasives.

Thebulkdensityof Sol-gelaluminaabrasivegrain:

Grit designation | Mean diameter in um | Bulk Density(g/cm3) |

F16 | 1230 | 1.76-2.00 |

F20 | 1040 | 1.78-2.02 |

F22 | 885 | 1.78-2.02 |

F24 | 745 | 1.78-2.00 |

F30 | 625 | 1.77-2.00 |

F36 | 525 | 1.79-1.99 |

F40 | 438 | 1.75-1.96 |

F46 | 370 | 1.73-1.93 |

F54 | 310 | 1.76-1.95 |

F60 | 260 | 1.72-1.94 |

F70 | 218 | 1.70-1.92 |

F80 | 185 | 1.67-1.87 |

F90 | 154 | 1.65-1.86 |

F100 | 129 | 1.64-1.84 |

F120 | 109 | 1.63-1.82 |

F150 | 82 | 1.62-1.82 |

F180 | 69 | 1.60-1.80 |

F220 | 58 | 1.58-1.78 |

Contact us:

Contact Us

- Zhengzhou Haixu Abrasives Co., Ltd.

- Contact namePan Chen Chat Now

- Phone86-371-60900389

- AddressXingyang, Zhengzhou, Henan

Product Categories

New Products

-

White Fused Alumina Grit Sandblasting

-

Brown Fused Alumina/BFA Abrasive Grain BFA GRIT

-

China White Fused Alumina/WA/WFA Manufacturer

-

A Grade Brown Aluminum Oxide BFA GRAIN

-

Black Silicon Carbide Powder JIS400 SiC Polishing Powder

-

foundry chromite sand AFS25-30 AFS30-35 AFS35-40 AFS40-45

-

Black Silicon Carbide Powder F320mesh/F400 mesh

-

black Silicon Carbide powder P Grit 1200 1500

-

Black Silicon Carbide Powder 10 microns

-

High Quality White Corundum 5-8mm For Refractory

-

high quality white fused alumina powder JIS1500#

-

Sandblasting Media Brown corundum BFA sand

-

high quality 99% Al2O3 white fused alumina/white corundum grit for sale

-

Green Emery SiC For Surface Treatment

-

polishing material black silicon carbide F800/JIS1500 for abrasive

-

white fused alumina powder JIS1500#

-

Brown Aluminum Oxide P Grit For Coated Abrasives

-

white fused alumina/white corundum grit for sale

Popular Searches

- grinding wheel

- cutting wheel

- Flap Disc

- ceramic ball

- refractory material

- corundum

- al2o3

- silicon carbide

- brown fused alumina

- White Fused Alumina

- hardware tools

- Fused Alumina

- ceramic plate

- Alumina Ceramic Tube

- Alumina Oxide

- Bulletproof Plate

- Alumina Powder

- ceramic tube

- aluminum oxide powder

- blasting

- Abrasive Material

- brown corundum

- bfa

- resin bonded

Recommended Products

- Polishing Abrasives Diamond Micron Powder Synthetic Diamond for Polishing

- Titanium Coated Synthetic Diamond / Coating Diamond Powder

- Polish Wool Flap Disc 4 1/2 Inch Angle Grinder Attachment for Stainless Steel Aluminum Polishing Metal Surface Chrome Finish for Cars, Trucks, SUVs, RVs, Motorcycles

- Wool Felt Flap Polishing Disc, Wool Polishing Wheel Disc Buffing Pad, Premium Felt Polishing Pads for Metal, Marble Stone, Furniture Car Wax

- Supply Polycrystalline Diamond Powder with High Sharpness

- High Strength Polycrystalline Diamond Powder for Silicong Carbide Polishing

- 1/2/3 Micron Polycrystalline Diamond Powder in Supply

- Supply Polycrystalline Diamond Powder for Precision Polishing

- High Quality Polycrystalline Diamond Powder for Sapphire Polishing

- Polyamide Nylon Deflashing Media for phenolic resin thermosetting plastic parts burrs cleaning

- Yttria-Stabilized Zirconia Beads for paint ink cosmetic grinding and shot peening

- Ceramic Shots for Auto Aircraft Parts Golf Club Surface Treatment Peening

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Pan Chen

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Pan Chen

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile