| Model | GL-200C | GL-300C | GL-400C | GL-500C | GL-600C |

| Width of Material (mm) | 200 | 300 | 400 | 500 | 600 |

| Thickness of Material (mm) | 0.5-4.5mm | ||||

| Coil Weight (Kg) | 1000kg | 2000kg | 2000kg | 3000kg | 3000kg |

| Coil I.D.(mm) | 450-530mm | ||||

| Coil O.D.(mm) | 1500mm | ||||

| Straightener Motor(HP) | 3HP | 3HP | 5HP | 7.5HP | 7.5HP |

| Feeding Speed (m/min) | 15M/Min | ||||

| Power Supply | 220V&380V | ||||

| Uncoil Expansion | Hydraulic Expansion | ||||

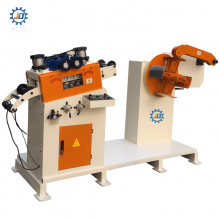

| Features and structure 1. The control box uses Japanese electronic parts, with few failures and long life. 2. Suitable for a wide range of materials with a thickness of 0.5-4.5mm, designed to save time and easy operation 3. Suitable for all kinds of precision parts, quick change of coils, saving time and reducing production costs. 4. Use manual expansion coil device, automatic control feeding, high safety, labor saving, precise structural design, suitable for heavy industry product needs. 5. Maintenance and management are simplified, and the safety of operators is enhanced. 6. The roller is made of solid bearing material, heat treated, chrome plated and then ground, with high hardness, excellent wear resistance and extremely long life. 7. This machine is equipped with a thick sheet pressing device for better effect. 8. This machine is equipped with a frequency converter. 9. This machine can be designed and manufactured according to customer's special requirements. 10. Use turbine fine adjustment leveling. 11. Cylinder in and out pressing. | |||||

| Product features: 1. This machine optimizes the material rack and the leveling machine into one, with beautiful appearance and compact structure, suitable for unwinding and leveling of medium plate coils with a thickness of 0.5 to 4.5 mm. 2. The material rack is powered, with pneumatic pressing arms pressing the material, and the discharging speed is controlled by the frequency converter. It runs smoothly and is reliable to use. 3. The entire machine box is welded with steel plates, and the welding surface is polished. After the box is welded, it is annealed and stress-relieved, and then the bearing holes are processed. The machine has small vibration during operation and stable operation 4. The leveling wheel is made of bearing steel (SUJ2), which is heat-treated to HRC60° and hard chrome-plated and then ground to have high hardness, high wear resistance and long service life. 5. The addition of the feed port support arm and the material head flattening device can facilitate the material to be pushed into the leveling machine head, making feeding convenient and quick. 6. The electronic control part uses imported electromagnetic contactors and electronic parts, which have long service life and few failures. 7. Optional hydraulic expansion method, photoelectric control discharging device, and increased spindle load capacity are available to meet customer customized needs. | |||||

| ●Standard accessories: Floor-type induction rack A-type material stop iron × 4 pieces Four-point fine-tuning device (scale) Pneumatic material pressing arm (material rack part) Frequency conversion speed regulation ●Special accessories: Hydraulic expansion device (material rack part) Photoelectric induction device Feeding trolley: can rise and fall, move forward and backward, and feed automatically ●Typical applications: Automatic unwinding and leveling operations for stamping of automotive hardware accessories, electrical hardware accessories, electronic hardware accessories, lock hardware accessories, etc. | |||||

Send Inquiry to This Supplier

You May Also Like

-

Punching Steel Bar Decoiler and Straightening Two-in-one Equipment Two-in-one Straightener Machine PriceUS$ 2000 - 3000MOQ: 1 Set

-

Automatic High-precision Three-in-one High Thickness Straightener Feeder Punch Three-in-one High Speed Feeder MachineUS$ 2000 - 3000MOQ: 1 Set

-

Punch Sheet Metal Material Rack Machine Heavy DutyUS$ 2000 - 3000MOQ: 1 Set

-

Precision Type Decoiler With Straightener Two-in-oneUS$ 2000 - 3000MOQ: 1 Set

-

3-in-1 Mid-thickness Straightener Feeder Equipment Three-in-one Straightener Feeder PriceUS$ 2000 - 3000MOQ: 1 Set

-

Punch Steel Bar Three-in-one Uncoiler Straightener Feeder MachineUS$ 200 - 300MOQ: 1 Set

-

Punching Steel Bar Decoiler and Straightening Two-in-one Equipment Two-in-one Decoiler StraightenerUS$ 2000 - 3000MOQ: 1 Set

-

Standard Type Decoiler With Straightener Two-in-one High Precision Variable StraightenerUS$ 200 - 300MOQ: 1 Set

-

Precision Type Decoiler With Straightener Two-in-one Decoiler and Straightener Two-in-oneUS$ 2000 - 3000MOQ: 1 Set

-

Tire Shredder Single Shaft Shredder Shredding MachineNegotiableMOQ: 1 Set