Home > Products > Wear Plate > Wodon A36 Steel Plate Super Wear-Resistant Chromium Carbide Overlay Coil Type Cutting Processing Services Meeting ANSI BS

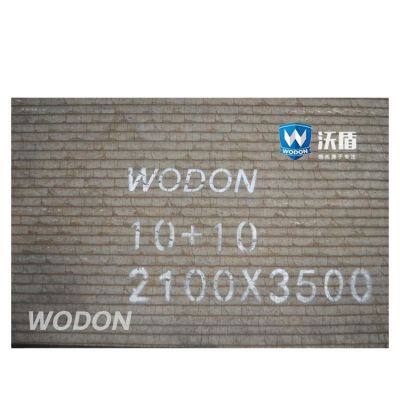

Wodon A36 Steel Plate Super Wear-Resistant Chromium Carbide Overlay Coil Type Cutting Processing Services Meeting ANSI BS

- 1000 Square Meter / Square Meters per Month

- T/T Credit Card

You May Like

-

Wodon factory chromium carbide overlay with high HRC 58-65 CCO wear plate (WD1200 series)

-

Wear Plate for Cement Mills High Impact Resistance Chromium Carbide Overlay Long Service Life

-

Wear Steel Plate Liner Coal Chute Bunker ASTM Wear-Resistant Steel Custom Including Cutting Welding Bending Punching

-

Wear Steel Plate Liner Coal Chute Bunker ASTM Wear-Resistant Steel Custom Including Cutting Welding Bending Punching

-

Wear-resistant lining plate for the inner part of the mining feeding chute

-

Chute Wear Liners Customizable Processing Services Cutting Bending Welding

Product Description

| item | value |

| Place of Origin | China |

| - | Jiangsu |

| Application | Ship Plate |

| Brand Name | WODON |

1.Advanced Cladding and Coating Technology: The Wodon Super Wear-Resistant Steel Plate is equipped with a Chrome Carbide Overlay Sheet or Coil Type to enhance its durability and resistance to wear and tear. This technology ensures that the plate maintains its super wear-resistant properties, providing exceptional performance during cutting processing services.

2.Robust Hardfacing and Welding Techniques: Utilizing hardfacing and open arc welding or submerged arc welding techniques, the Wodon Steel Plate ensures optimal impact resistance and high-quality bonding. This advanced solution guarantees a strong bond and enduring performance, even under extreme conditions.

3.Optimal Hardness Levels: The plate boasts a hardness of 58-65HRC, offering the ideal balance of strength and toughness for effective cutting processing. This hardness level ensures that the plate can withstand high levels of stress and wear, prolonging its lifespan and maintaining its performance capabilities.

4.Customizable Microstructure and Chemical Composition: The Wodon Steel Plate incorporates Carbide (Cr7C3) volume fraction above 50%, along with a precise chemical composition of C:3-5%, Cr:25-40%, Mn:1-3%, Si:1-3%, and Fe: balance. This customization allows for tailored microstructures and chemical compositions to address varying processing requirements and applications.

5.Enhanced Flatness Tolerance and Tolerance Accuracy: The Wodon Steel Plate achieves a flatness tolerance of ±3mm/m and a tight tolerance of ±3%, ensuring a consistent manufacturing process and reliable performance. This advanced manufacturing technology allows for accurate and precise flatness profiles, suitable for applications such as ship plate and wear-resistant steel uses.

Jiangsu Wodon Wear Resistant Material Co., Ltd. (China Wodon) is a leading manufacturing company specializing in the research and development of wear-resistant materials with over 500 employees, including 35 experienced R&D engineers. The company is headquartered in Jiangsu, a major port hub in North China, offering a wide range of products such as chromium carbide overlay (CCO) wear plates and flux cored hardfacing welding wires.

Wodon is a pioneer in providing high-quality, innovative wear solutions and boasts a strong research and debugging team with independent intellectual property rights and numerous patents. With a regional distribution of 4 major production bases covering Jiangsu, Hebei, Hunan, and Jiangsu, the company operates 109 wear plate production lines and seven hardfacing wire production lines. Annual production capabilities include 260,000 square meters of chromium carbide wear plates and 16,000 tons of flux cored hardfacing wires.

Wodon is committed to delivering cost-effective solutions that meet even the most demanding needs of clients. With a network of technical consultants from the wear-resistant industry and a dedication to staying ahead in technology, the company is poised to continue revolutionizing the wear-resistant materials sector and providing exceptional service.

1. who are we?

We are based in Jiangsu, China, start from 2014,sell to Domestic Market(55.00%),Oceania(15.00%),North America(8.00%),South America(5.00%),Eastern Asia(5.00%),Eastern Europe(5.00%),Southeast Asia(5.00%),Africa(2.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Chromium Carbide Overlay Plate, Flux Cored Welding Wire, Wear Plate Liner

4. why should you buy from us not from other suppliers?

The chromium content as high as 25~50% in the overlay

The chromium carbide (Cr7C3) volume fraction above 50%

Uniform distribution and high hardness HRC 58~65

Smooth surface, thickness tolerance +0~+0.5 mm only

Flatness tolerance -3~+3 mm/m

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency: USD,EUR,CAD,AUD,CNY;

Accepted Payment Type: T/T,L/C,Cash;

Language Spoken: English,Chinese,Spanish,Portuguese,German

Company Profile

Jiangsu Wodon Wear Resistant New Material Co., Ltd. (China Wodon) is a manufacturing factory specializing in the development and production of wear resistant materials. We are headquartered in Jiangsu. There are over 500 staff, including 60 experienced R&D engineers. Our main products include: chromium carbide overlay (CCO) wear plates, flux cored hardfacing welding wires, etc. With independent intellectual property rights and a number of patents, it has a strong R&D and debugging team, which can provide customers with a streamlined service.

Since its inception, with the huge investment and independent technology research and innovation, Wodon has been taking the lead in providing premium quality CCO wear plates, hardfacing welding wires as well as excellent repairing technique, all of which win trust and acceptance from our clients worldwide. Meanwhile, the company also employs many experts and professors in the wear resistant industry as the company's technical consultant to ensure strong technical strength and production capacity, we are dedicated to providing quality and cost-effective wear solutions that completely fulfill the requirements of clients.

Contact Us

- Jiangsu Wodon Wear Resistant New Material Co., Ltd.

- Contact namezhang Chat Now

- Addresshongze, Huaian, Jiangsu

Product Categories

| Ungrouped | Wear Components | Wear Pipes and Fittings | Wear Plate |

| Welding Wires | Wear parts |

New Products

-

Hardfacing wear resistant flux cored welding wire

-

WODON anti wear gas shield flux cored 15kg per coil package co2 welding wire

-

Vertical cement mill hardfacing flux cored welding wire

-

Squeeze roller hardfacing flux cored welding wire

-

WODON reliable hard face flux cored coal scraper conveyor welding wire

-

flux cored welding wires for wear plate wear resistant plate hardfacing wires producer in China

-

China manufacturer 2.8 mm open arc welding flux cored welding wire

-

1.2mm 1.6mm gas shielding wear resistance CO2 mig abrasion resistant welding wire

-

250kg drum packing hard face flux cored wire wear plate welding wire

-

hardfacing soldering wire WD-D990+ high temperature flux cored welding wire

-

China Factory's Corrosion-Resistant Flux Core Wire for General Welding & Surfacing High Quality Metals & Metal Products

-

Wodon abrasion resistant heat resistant flux core welding wire

-

Wodon Customizable OEM Gas Shielding Flux Cored Welding Wire for Surfacing Valve Application

-

Hardfacing fluxed cored welding wire FCW wear resistant for single layer hardfacing WD-D788A 1,2mm

-

wear resistant flux cored welding wires for wear plates

-

China Manufacturer's CO2 Gas Shielded Welding Wire Alloy Flux Cored Wire for Soldering from Production Line

-

HB100 Vertical Cement Mill Welding Wires High Performance for Excellent Results

-

Wodon manufactured high chromium high carbon flux core wire for surface welding wear plate

-

HB350 abrasion resistant hardfacing co2 welding wire for cement mill roller surface repair

-

Flux Cored Welding Wire Abrasive Resistant for Single Toothed Roller Crusher & Sintering Machine Metals & Metal Products

-

Flux Core Welding Wires for Vertical Cement Mill High Performance for Hardfacing Repair of Metal Roller

-

mig welding wire flux cored welding wire for sale

-

Wear resistant flux cored welding wire for hardfacing wear plate

-

HB-YD788 Customizable Soldering Wire Super Wear-Resistant Hardfacing Welding Repair Structural Components-Tin Steel Silver

Popular Searches

- Magnesium Ingot

- Magnesium Alloy Ingot

- Magnesium Alloy

- gallium

- metallurgy

- anode

- Cu Sn Alloy

- magnesium

- magnesium plate

- Mg Ingot

- Magnesium Ingots

- germanium ingot

- cadmium

- ferro chrome

- Carbon Ferrochrome

- gallium metal

- Metal Cobalt

- ferro chrome alloy

- magnesium rod

- magnesium pipe

- magnesium alloy sacrificial anode

- magnesium alloy bar

- az91

- Metal Lump

- capacitor tantalum

- germanium

- zirconium rod

- zirconium tube

- zirconium bar

- magnesium metal powder

Find Similar Products By Category

- Minerals & Metallurgy > Other Metals & Metal Products

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

zhang

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

zhang

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile