Home > Products > AOB oil burner > Asphalt Plant Burner Heating high quality Waste Oil Burner for boiler

You May Like

-

Industrial Gas Light Oil Diesel One Stage Boiler Accessory Oil Fired Burner

-

Light Oil ,Diesel burner ,Boiler Accessory, Reactor spare parts

-

High Quality And Famous Brand Diesel Heavy Oil And Natural Gas Burner For Industrial Boiler

-

wholesale oil burner diesel oil burner boiler parts oil burner factory

-

Asphalt Mixing Plant Gas Burners Industrial Stationary Mini Asphalt Mixing Plant Burners

-

Industrial Heating Equipment Large Asphalt Mixing Plant Burner, Asphalt Mixing Plant Use Gas Burner

Product Details

| Brand Name | FARRBURNER | Place of Origin | China | |

| Model Number | AOB500 | Type | Oil Burner |

Product Description

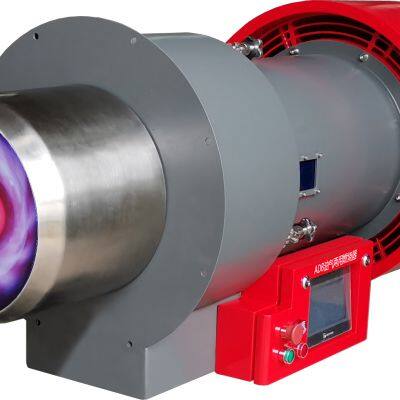

AOB oil type burner

Performance characteristics of the burner

Farr burners are designed with CFD combustion simulation technology, which uses the powerful computing function of the computer combined with computational fluid dynamics to simulate the operation of the burner and the furnace body (including the temperature field, flow field, flame shape, combustion products, aggregate temperature, etc.). At the same time, the effect of fuel and air distribution on complete combustion can be simulated in a virtual environment according to the actual drum geometry.

Burner product performance parameter table

Technical characteristics

(1) Compliance with standards: in line with the international CE, DIN standards and GB national standard requirements, fully in line with the standard

(2) Oil control temperature ±1℃ : independent patent heater, small size, large power, corrosion resistance, long life. Achieve ±1℃ high control accuracy, to solve the impact of oil temperature fluctuations.

(3) 2% fine control of atomization gas volume: special structure adjustment valve, accurate regulation technology, so that the atomization gas volume is controlled at 2%, different loads are used under different atomization gas volume. The super load adjustment ratio of 1:10 can still ensure the flame stability under the large adjustment range.

(4) Oil precision control ±1% : real-time online monitoring of fuel volume changes, can display instantaneous, cumulative flow, single production fuel consumption, etc. The system automatically compensates the fuel amount to the target amount, and the deviation control reaches ±1% accuracy. Without flowmeters, it is impossible to save fuel!

(5) Air oil ratio adjustment: Based on the flow monitoring function, the air volume changes synchronously with the oil volume, so that the ratio of wind and oil in the combustion process is 100% accurate, and the possibility of ratio deviation is avoided.

(6) Self-judgment of oil pump wear rate: the system automatically determines the output capacity of the oil pump, while the combustion system automatically corrects the output capacity, which can extend the service life of the oil pump, and the combustion system will show the wear degree of the oil pump.

(7) Automatic alarm for oil pump replacement: When the oil pump is worn to the point that it cannot be used, the combustion system will issue a pump change alarm and prompt in advance, reserving enough time to prepare the pump head, and will not shut down to affect production.

(8) wear-resistant pump: high-end configuration wear-resistant pump, we promise to wear within 10 months, unconditional replacement (except for human factors), the service life is more than 16 times that of ordinary pumps.

(9) Pipeline electric heat tracing: All pipelines, pumps, valves are covered by electric tracing tropical, outsourcing insulation materials, 99.99 percent without dead corners. Even if the ambient temperature is lower than -10℃, it can also be stable and reliable combustion.

(10) High ignition success rate of heavy oil: The use of pipeline dredging, pre-heating, circulating oil and other technologies to achieve 100 percent success rate of direct ignition of heavy oil, without switching light oil ignition.

(11) Double oil valve: the national standard and the European label stipulate that the burner greater than 100kg/h should be set with "two series cut-off valves", and the double oil valve can solve the problem caused by leakage.

(12) Low nitrogen combustion technology: The use of advanced stratified combustion and air distribution technology, greatly reducing nitrogen oxide emissions, in line with environmental standards. Low nitrogen combustion, walking in the forefront of environmental protection technology!

(13) Remote diagnosis and processing: combustion engineers monitor the operating status remotely and in real time through the grid to guide quick troubleshooting. Without remote service, it is impossible to do "urgent customer"!

Burner installation precautions

For the installation of the combustion system, the following aspects should be paid attention to:

1. Installation of burner body. According to the actual situation of the site, combined with the overall size of the burner, determine the direction arrangement of the drum, gas pipeline and air duct (split machine). The interface flange of the burner and the roller needs to be made by the customer on site.

2. Installation of valve group. The gas valve group of the AGB gas burner does not have the function of pressure regulation and pressure regulation, so the user needs to do a good job of pressure regulation and pressure reduction at the front end of the gas supply, and the valve group does not have a filter, so the front end pipeline should be fully purged before the use of the new pipeline to avoid a lot of debris into the valve group.

3. Installation of control cabinet. In strict accordance with the construction of the circuit diagram, the control cabinet is equipped with a remote connection module. When the system is not working normally, or when a remote engineer is needed to assist in debugging or fault diagnosis, the Internet can be connected through the mobile phone WIFI sharing, and the remote engineer can connect to diagnose the fault, which can greatly shorten the time of sending personnel to solve the on-site fault.

4. Installation of fuel pump group. The fuel pump group should be set within 3 meters of the tank outlet (too long a distance may lead to oil supply failure), and the diameter of the pipe before the pump group should be DN50, and the diameter should be changed to DN40 before the pump group. All the return pipelines are DN25, which can be directly returned to the upper liquid level of the oil tank. No other valve can be set on the return pipeline to prevent overpressure burst caused by misoperation of the valve.

About US

Main business: boiler, kiln, construction machinery industry to provide a complete set of combustion solutions and technical services, to provide intelligent equipment control system, to provide flue gas and dust environmental protection equipment.

Company Profile

Quanzhou Farr Machinery Technology Co., Ltd. has been engaged in the boiler, kiln, and construction machinery combustion industry for more than two decades, with over ten years of experience in providing supporting equipment for asphalt mixing and burning. It is a technology-oriented enterprise.The company relies on its advanced production equipment, reliable research and development team, scientific production processes, and cutting-edge manufacturing techniques. Adhering to the core values of "serving with heart in the era of technology to win the future," it prioritizes user needs, aiming to provide high-standard products and thoughtful services, ensuring users achieve sustained benefits.In 2018, it became an authorized company of Britain's FARR, sharing its patented technologies and gaining the rights to produce and sell its branded products.Research and development of production technology for mechanical equipment; Manufacturing: mechanical parts, boilers, hardware products (excluding electroplating); Sales: Instruments and meters, building materials (excluding hazardous chemicals), electrical equipment accessories, and automation control systems; Anime design; Computer network system engineering services, information system integration services, and air pollution control. (For projects that require approval by law, business activities can only be carried out after approval by relevant departments)

Contact Us

- Quanzhou Farr Machinery Technology Co., Ltd

- Contact nameZhongtao Chat Now

- Phone86-13675910481

Product Categories

| ADB oil and gas burner | AOB oil burner | AGB gas burner | Oil pump |

| Electric oil heater | Quick-open filter |

New Products

-

Small Burner for Boilers/Asphalt Mixing Plant

-

Hot Sale Liquid Industrial Fuel Two Stage Light Heavy Diesel Oil Fired Burner for Asphalt Plant Waste Oil Burner

-

Low Price Asphalt Mixing Plant Bitumen Oil Burner Hot Mix Asphalt Mixing Plant Burner

-

Asphalt & Construction Plants Oil Burner Waste Dirty Vegetable Oil Hydraulic Oil Burner

-

Factory Direct Supply Burner Nozzle Asphalt Plant Hot Mix Asphalt Machine Burner

-

Asphalt mixing plant special burner oil and gas dual-use models complete

-

Asphalt mixing plant burner New type of burner combustion equipment strong corrosion resistance low fuel consumption

-

Farr burner low nitrogen methanol oil alcohol based energy saving automatic burner

-

Large Asphalt Mixing Plant Burner, Asphalt Mixing Plant Use Gas Burner Factory Price

-

High Precision Burner for The Asphalt Mixing Plant Special Electronic Intelligent

-

Hot Mix Low Price Asphalt Mixing Plant Bitumen Oil Burner Asphalt Mixing Plant Burner

-

Gas Burners Industrial Asphalt Mixing Plant Mini Asphalt Mixing Plant Burners

-

Asphalt Mixing Plant Dryer Drum Diesel Heavy Oil Waste Oil Burner Asphalt Mixing Plant Burner

-

Temperature Adjustment High Speed Gas Burner

-

Industrial Using/ Home Using Heating Equipment Waste Oil Burner Spare Parts Wax Warmer Oil Burner

-

Small high pressure gas burner Gas industrial gas burner for industry

-

Manufacturers wholesale oil burner boiler with industrial aluminum alloy light oil burner

-

Industrial Gas burner China burner manufacturer small gas industrial burner

-

Asphalt machine burner Air atomizing burner models are complete

-

Low nitrogen burners alcohol-based fuel burners alcohol-based combustion equipment support customization

-

Low nitrogen burner Gas burner heat conduction oil boiler accessories oil and gas dual use

-

Asphalt mixing plant burner New type of burner combustion equipment strong corrosion resistance low fuel consumption

-

Ultra-low nitrogen burner gas low nitrogen burner large calorie biomass particle combustion

-

heavy oil burner oil and gas burner industrial direct burning new energy combustion equipment

Popular Searches

- sewing machine

- Dyeing Machine

- steam boiler

- steam generator

- hot water boiler

- gas heater

- industrial boiler

- Textile Machine

- gas burner

- candle warmer

- ceramic home decoration

- ceramic gift item

- aroma burner

- asphalt mixing plant

- waste oil burner

- Mixing Plant Burner

- spray nozzle

- steam boiler

- hot water boiler

- gas burner

- Oil Heater

- candle holder

- Waste Oil Heater

- Cooking Stove

- gas fired boiler

- Water Tube Boiler

- automatic burner

- light oil burner

- oil warmer

- Diesel Burner

Find Similar Products By Category

- Machinery > General Industrial Equipment > Boilers & Parts > Boiler Parts