Home > Products > Toy packaging machine > Large particle building block toy automatic packaging line puzzle building block particle packaging machine assembling particle toy packaging machine

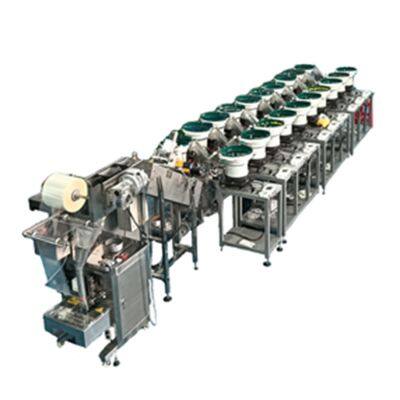

Large particle building block toy automatic packaging line puzzle building block particle packaging machine assembling particle toy packaging machine

≥1 Piece

- 100 Piece / Pieces per Month

- Shenzhen

- T/T L/C PayPal D/P Western Union Other

- 30 days

You May Like

-

Lego Toy Assembly Automatic Subcontracting and Assembly Series Automatic Production Line Lego Toy Packaging Machine

-

Toy Particle Quantitative Packaging Machine AI Visual Inspection Toy Production Line Lego Block Accessories Packaging Equipment

-

Fully automatic granule bagging machine, food vacuum bagging machine, zipper automatic packaging machine, snack granule packaging machine

-

Fully automatic granular melon seed and nut weighing vacuumpackaging equipment Food quantitative packaging machine Pre made bag feeding machine

-

Small food granule automatic packaging machine, powder quantitative small bag sorting machine, liquid packaging machine

Product Details

| Place of Origin | China | After-sales Service Provided | No overseas service provided | |

| Application | Other, Building block particles | Condition | New | |

| Automatic Grade | Automatic | Driven Type | Mechanical | |

| Packaging Material | Metal, Plastic | Packaging Type | Pouch, Stand-up Pouch |

Product Description

Automated toy building block production line

As an automated packaging equipment for building block products, the advantages of the Juzhan automatic building block toy packaging machine mainly lie in efficiency, precision, flexibility, and cost control. Combined with the product characteristics of building block toys (such as multiple components, diverse specifications, and the need to balance aesthetics and protection), the specific advantages can be summarized as follows: 1. Efficient automated production, greatly improving packaging efficiency

1. High speed operation: Through technologies such as servo motors and intelligent conveyor belts, high-speed sorting, counting, and bagging/boxing can be achieved, which increases efficiency by 50% -100% compared to manual packaging. It is particularly suitable for the large-scale production needs of building block toys.

2. 24-hour continuous operation * *: supports 24/7 operations, reduces manual fatigue and intermittent losses, significantly improves production capacity, and meets emergency production needs during peak seasons or when orders surge.

2、 Precise control to ensure consistency in packaging quality

1. Accurate counting of components: Equipped with a visual recognition system (such as CCD camera) or weighing sensor, it can accurately detect the number of building block particles, avoid missing or incorrect installation, and reduce the risk of after-sales complaints.

2. Standardized packaging process * *: From feeding, packaging to sealing and labeling, the entire process is parameterized and controlled to ensure that the size, sealing, and appearance of each package are consistent, enhancing the brand image. 3. * * Stable protective performance * *: In response to the characteristics of easy scattering and fear of compression of building block toys, it can automatically complete protective processes such as bubble film filling and vacuum box fixation, reducing transportation losses.

3、 Flexible adaptation to multiple specifications of products, reducing the cost of changeover

1. Quickly switch molds/programs: preset packaging parameters for different building block sets (such as box size, part quantity, packaging form) through the human-machine interface (HMI), switch production modes with one click, and adapt to the market demand for building block toys with multiple SKUs and fast updates (such as sets with different themes and particle numbers).

2. Compatible with multiple packaging forms: supports diversified packaging such as plastic bags, paper boxes, vacuum formed boxes, gift sets, etc., and can integrate functions such as card insertion, manual folding, anti-counterfeiting label pasting, etc., to meet the needs of different sales scenarios (retail, e-commerce, gift boxes).

4、 Reduce labor costs and management difficulties

1. Reduce labor dependence: Only 1-2 people are needed to monitor a single packaging line, saving more than 70% of labor compared to traditional manual packaging, especially alleviating the "labor shortage" problem in the manufacturing industry.

2. Data management: Real time recording of production volume, yield rate, equipment status, and other data through PLC control system or Internet of Things (IoT), facilitating production scheduling and quality traceability, and improving the level of factory intelligence.

5、 Environmental Protection and Safety Compliance

1. Material compatibility: Supports biodegradable packaging materials (such as corn starch based plastic bags, environmentally friendly paper boxes), in line with the global trend of green packaging, and avoids export barriers caused by non-compliance with environmental standards.

2. Safety protection design: equipped with overload protection, emergency stop device, anti pinch sensor, etc., to ensure the safety of operators and avoid equipment failure causing damage to products.

3. The automatic building block toy packaging machine solves the pain points of counting errors, chaotic specifications, and low manual efficiency that are prone to occur in building block product packaging through the core advantages of "efficiency+precision+flexibility". At the same time, it also takes into account cost control and quality upgrading, becoming a key equipment for building block toy production enterprises to enhance their competitiveness. In the future, with the development of AI vision technology and flexible manufacturing, its intelligence and adaptability will be further enhanced, adapting to more complex scenarios.

Contact Us

- Dongguan Juzhan Intelligent Technology Co., Ltd

- Contact nameZhang Chat Now

Product Categories

| Toy packaging machine | Bag packaging machine |

Popular Searches

- Apparel Cutting Machine

- Boxing Machine

- Boxing Equipment

- apparel plotter

- reel stand

- Box Making Machine

- Box Forming Machine

- Paper Box Forming Machine

- Paper Box Making Machine

- Jewelry Box Making Machine

- Carton Box Forming Machine

- cartoning machine

- package machine

- pasting machine

- Silica Gel Desiccant Packet

- carton machine

- stitcher

- carton stapler

- Tissue Packing Machine

- Tissue Packaging Machine

- Alcohol Making Equipment

- detergent powder production line

- detergent powder package machine

- Packing Production Line

- automatic package machinery

- automatic case maker

- Pizza Box Making Machine

- Biscuit Packing Machine

- Biscuit Packaging Machine

- Packaging Production Line

Recommended Products

- Z Type Coffee Beans Bucket Lift Conveyor

- Z Type Chain Bucket Conveyor for Nuts Candy

- Horizontal Conveying Z Type Elevator Conveyor for Snacks

- Z-Type Vertical Bucket Elevator 304 Stainless Steel Food-Grade Conveyor

- Automatic Conveyor Feeder Hopper Bucket Conveyor for Food Snacks Nuts

- Z Type Bucket Elevator Conveyor for Bean Nuts

- Food Grade Z Type Bucket Elevator Conveyor for Nuts Grains Snacks

- Automatic Vertical Feeding Transport Z Type Bucket Conveyor for Popcorn Snack

- Food Grade Stainless Steel Sugar Powder Z Type Industry Bucket Elevator

- Food Grade Conveyor Automatic Vertical Z Type Bucket Elevator

- Automatic Small Tea Sugar Coffee Sachet Filter Paper Tea Powder Pouch Packaging Machine

- Pack Tea Automatic Round Tea Bag Packaging Machine

Find Similar Products By Category

- Machinery > Packaging Machine > Packaging Line

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Zhang

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Zhang

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile